FM-I HIG: Custom EPDM Granules for Turf Infill Series |Safeguard student athletic safety

group nameFor Turf Infill Series

-

Min Order1 piece

brand nameFieldsMaster EPDM Granule Manufacturer

modelFM-I HIG

payment methodT/T, L/C, D/P D/A, Credit Card, PayPal

-

update timeFri, 08 Nov 2024 11:14:44 GMT

Paramtents

Color range customizable

Tensile strength 4.56Pa

Elongation at break 440%

Packging & Delivery

Min Order1 piece

Briefing

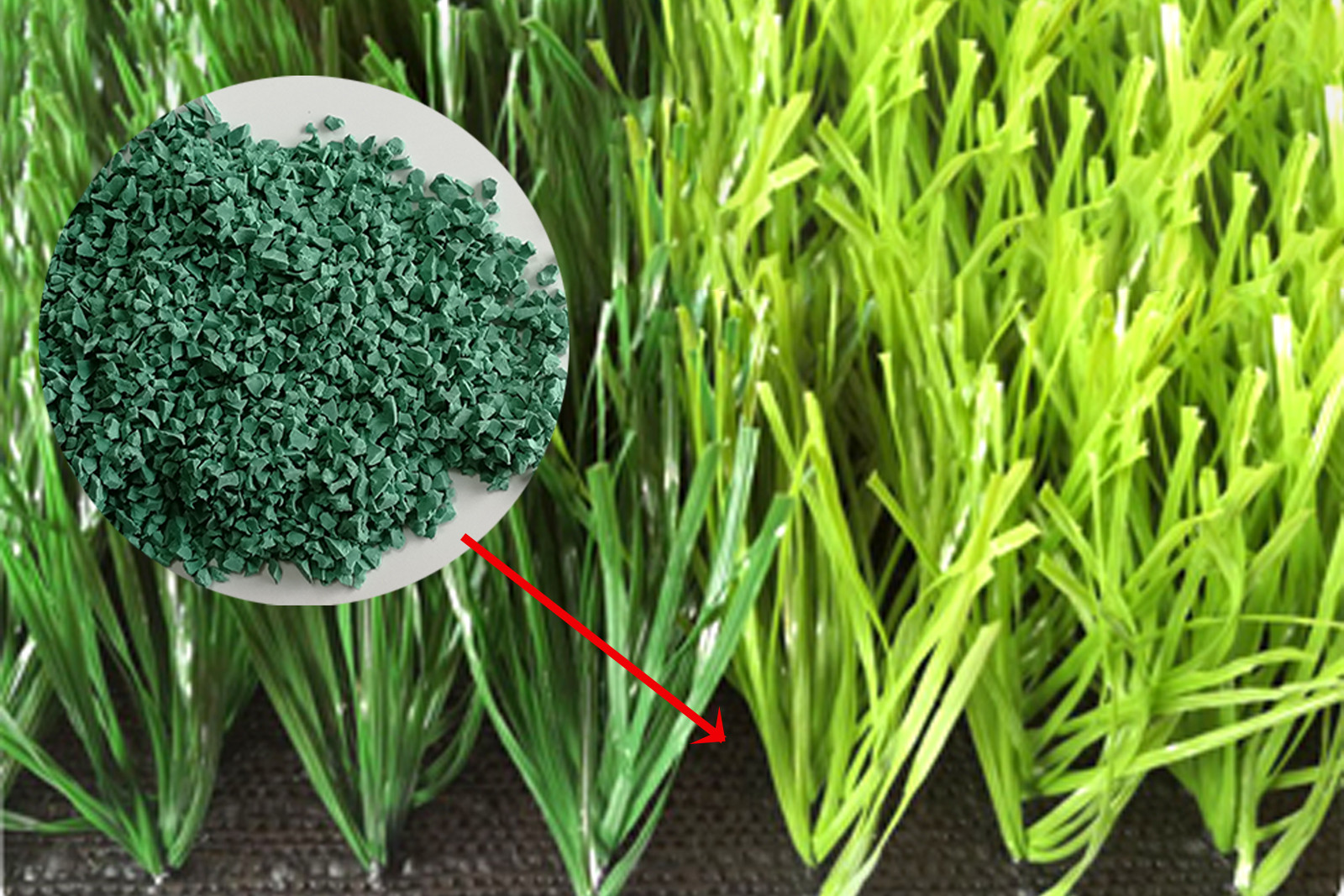

Elevate your turf with FieldsMaster EPDM infill granules for top-notch sports performance and safety.

Detailed

Property | Value | Unit | Standard | / |

Polymer content | 20 | % | DIN EN ISO 3451-1(2019) | / |

Tensile strength | 4.56 | MPa | DIN 53504(2017) | / |

Elongation at break | 440 | % | DIN 53504(2017) | |

Hardness | 60 ± 5 | Shore A | ISO 48-4(2018) | |

Density | 1.50± 0.05 | g/cm3 | DIN EN ISO 1183-1(2019) | |

Bulk density | 667 | g / L | EN 1097-3(1998) | |

Grey Scale Assessing | 4-5 | \ | DIN EN 20105-A02(1994) | |

Base polymer | EPDM – ethylene propylene diene monomer rubber | |||

Content: EPDM - Etylen Propylen Dien Monomer, mineral fillers, plasticizer, vulcanising agents, additives, pigments | ||||

Flammability class | Ⅰ | GB/T22517.62020 | ||

Epdm Granules Environmental Parameters | |

Standard | Result |

GB 36246-2018 Toxic substance(Total 18 PAHs) | Fulfills requirements |

(EC)No.1907/2006(REACH)SVHC | Fulfills requirements |

EN 71-3:2019+A1:2021- Migration of certain elements | Fulfills requirements |

A: Warranty period: The warranty period specified in the sales contract is usually a certain number of years, such as one year, two years or more.

A: Cleaning: Regularly remove debris and dust on the surface of EPDM granules. You can use a soft brush or vacuum cleaner to ensure that the EPDM surface is clean.

You need a product

You May Like

- Nearest port for product export

- Port of Shanghai, Port of NingBo

- Delivery clauses under the trade mode

- FOB, CIF, EXW, DDP, DDU

- Acceptable payment methods

- T/T, L/C, D/P D/A, Credit Card, PayPal