Stainless Steel Wastewater Treatment DAF System Dissolved Air Flotation For Industrial Sewage

group nameDissolved Air Flotation System

-

Min Order1 piece

brand nameAquaSust Wastewater Treatment Solutions

modelDissolved Air Flotation

payment methodL/C, D/A, D/P

-

update timeFri, 08 Nov 2024 22:45:34 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Dissolved Air Flotation Introduction

Dissolved Air Flotation Advantages:

Dissolved Air Flotation Introduction Parameters

|

PARAMETERS

|

|||

|

Model

|

Treatment Capacity(m3/h)

|

Dissolved Gas Volum(m3/h) | Weight(T) |

|

ASDAF-5

|

5

|

1-2 | 2.1 |

|

ASDAF-10

|

10

|

2-3 | 3.2 |

ASDAF-20 | 20 | 5-7 | 3.6 |

ASDAF-30 | 30 | 6-10 | 3.9 |

ASDAF-50 | 50 | 15-20 | 5.6 |

ASDAF-80 | 80 | 24-32 | 7.6 |

ASDAF-100 | 100 | 30-35 | 11.5 |

ASDAF-150 | 150 | 60-80 | 15 |

ASDAF-200 | 200 | 80-100 | 19 |

ASDAF-250 | 250 | 110-120 | 23 |

ASDAF-300 | 300 | 120-180 | 26 |

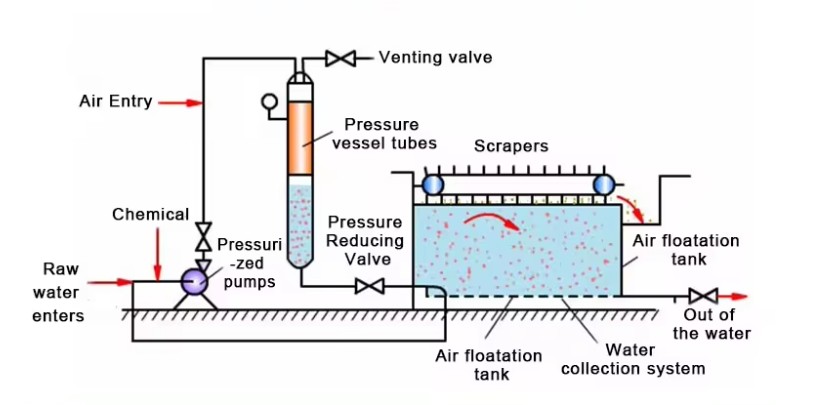

DAF Working Principle

Application in Various Industry

You need a product

You May Like

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A