Manufacturer Tube Settler AS-35PP | 35mm Lamella Settler for Shock resistance & Corrosion resistance | for Power Plant Wastewater Treatment

- US $35.00

10 - 1,000 cubic meter

- US $27.00

1,001 - 10,000 cubic meter

group namePVC Tube Settler

-

Min Order10 cubic meter

brand nameAquaSust Wastewater Treatment Solutions

modelAS-35PP

payment methodL/C, D/A, D/P

-

update timeFri, 08 Nov 2024 16:54:11 GMT

Paramtents

Material 100% New PP with UV protector

Color Blue or white

Service Life 5 to 10 years

Packging & Delivery

Weight0.42kg / cubic meter

Min Order10 cubic meter

Briefing

Detailed

Tube Diffuser AS-35PP Introduction

Category: Complementary Products - Tube Settler

Band: AquaSust

Model: AS-35PP

Size: 35mm

Gravity: 0.92g/cm3

Slope: 60°

Tube Settler AS-35PP Advantage

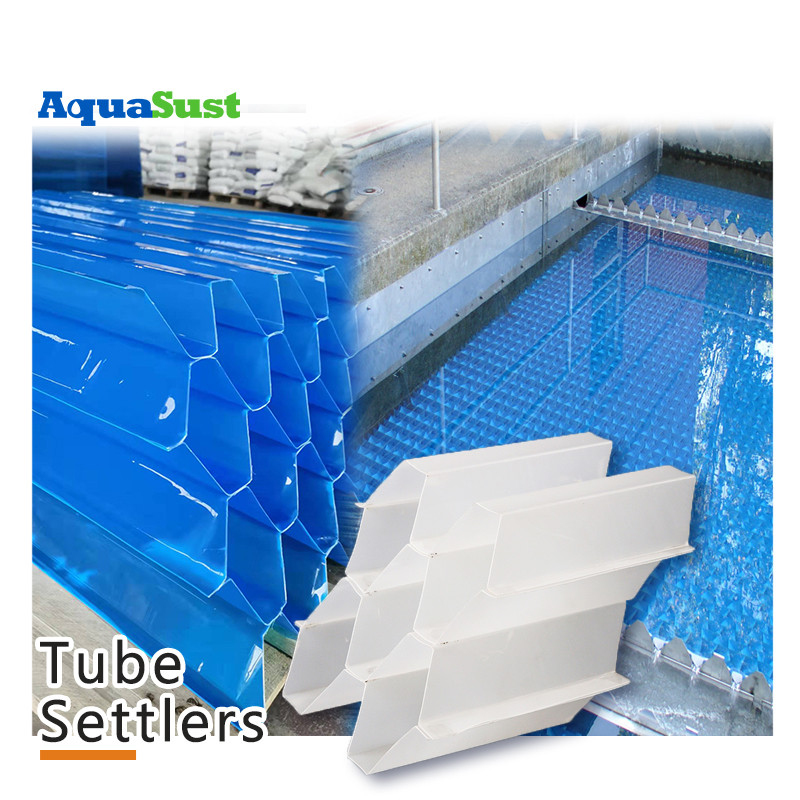

- The AS-35PP tube settler provides a robust solution for water treatment projects with excellent shock and corrosion resistance. This tube settler has been designed with special materials and construction that allow it to withstand sudden load changes and harsh chemical environments, ensuring continuity and stability of the water treatment process. Impact resistance means that the AS-35PP tube settler will remain operational even under extreme water impacts, with no loss of efficiency due to sudden increases in treatment capacity. Corrosion resistance, on the other hand, ensures that structural integrity and functional durability are maintained after prolonged exposure to corrosive chemicals, thus significantly extending the life of the equipment.

Tube Settler AS-35PP in Power Plant Wastewater Treatment Application

Model |

A

|

B

|

C | D | Material | Service Life | Surface Area |

AS-25PP | 30MM | 20MM | <20MM | ⌀25MM | pp+uv | 5-10Year | >95m2/m3 |

AS-35PP | 40MM | 20MM | <20MM | ⌀35MM | pp+uv | 5-10Year | >95m2/m3 |

AS-50PP | 60MM | 28MM | <30MM | ⌀50MM | pp+uv | 5-10Year | >95m2/m3 |

AS-80PP | 80MM | 35MM | <45MM | ⌀80MM | pp+uv | 5-10Year | >95m2/m3 |

You need a product

You May Like

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A