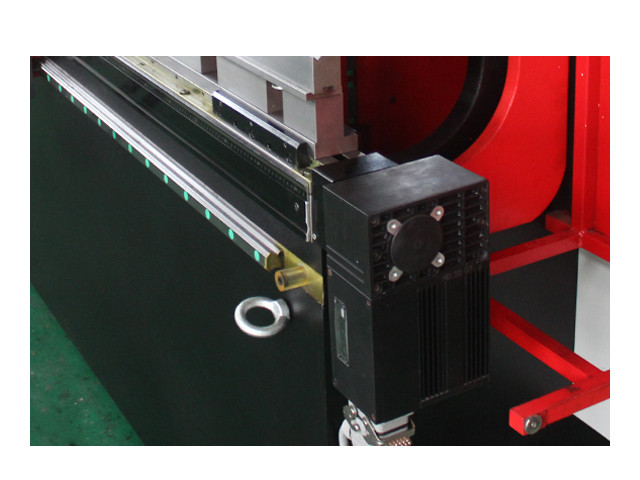

WF67K-M Series Hybrid CNC Press Brake Product Features: Waterproof and dustproof design ensures durability and stability in various working environments..

- US $4800.00

1 - 3 piece

- US $5000.00

4 - 9 piece

group namePress Brake

-

Min Order1 piece

brand nameMeteWorkMas Metal Processing Equipment Experts

modelWF67K-M 80T/2500

payment methodL/C, T/T

-

update timeSat, 09 Nov 2024 05:47:29 GMT

Paramtents

color Red and black

Machine Type Hybrid

Workbench length (mm) 2500 mm

Degree of automation Fully Automatic

Degree of oldness New

country of origin China

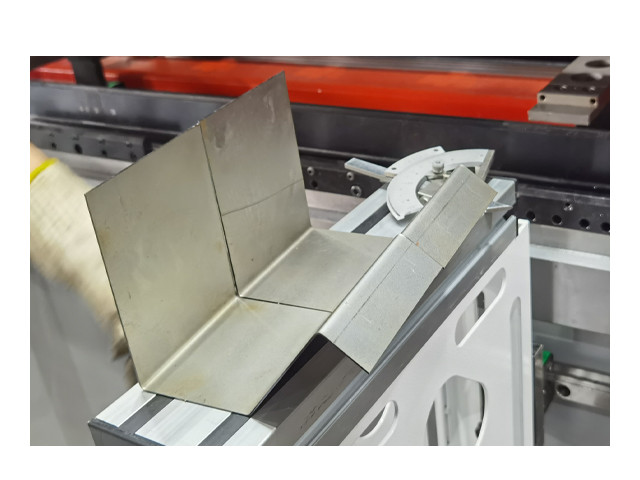

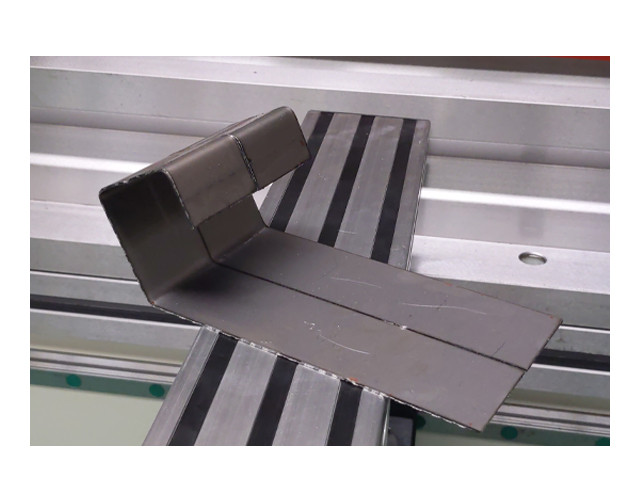

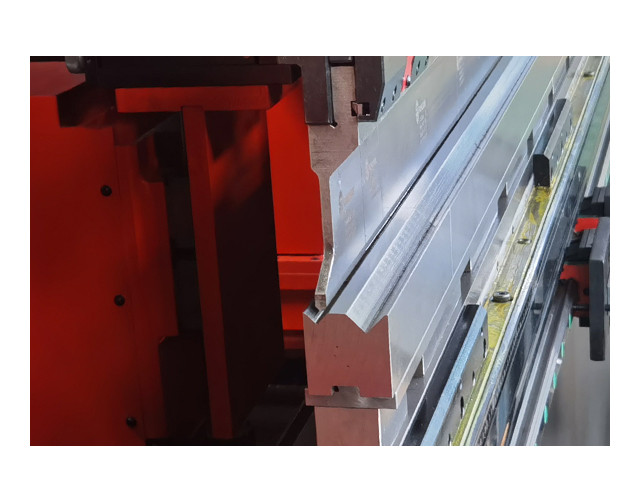

Machinable materials Mild Steel,Stainless Steel,Aluminum

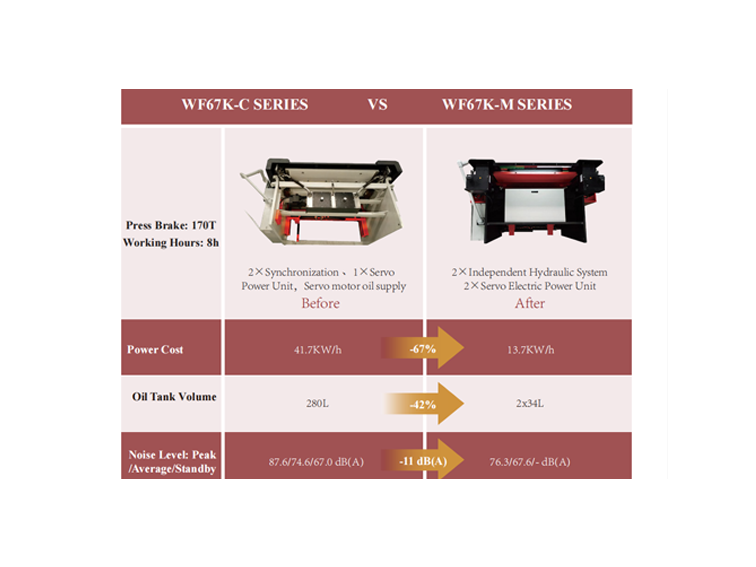

Core selling point Energy saving

Warranty 3 years

Marketing Type New Product 2024

Video factory inspection Provided

Mechanical test report Provided

Packging & Delivery

Size200cm x 20cm x 20cm

Weight60.00kg / piece

Min Order1 piece

Briefing

Detailed

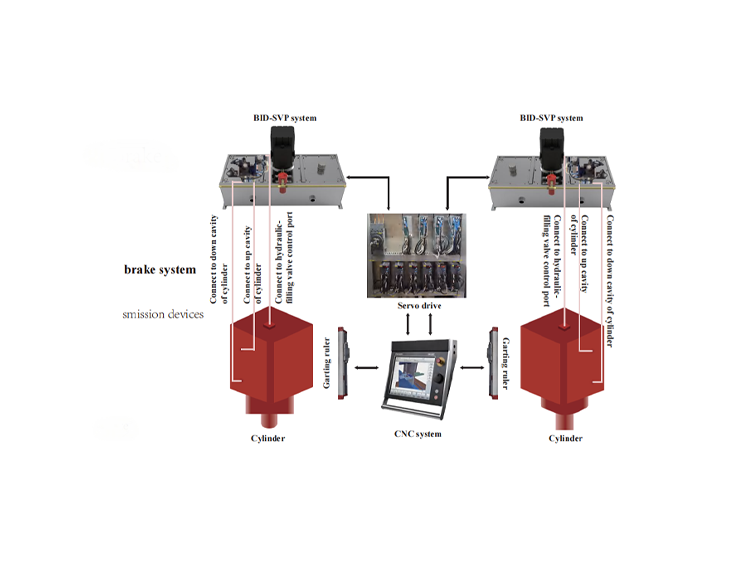

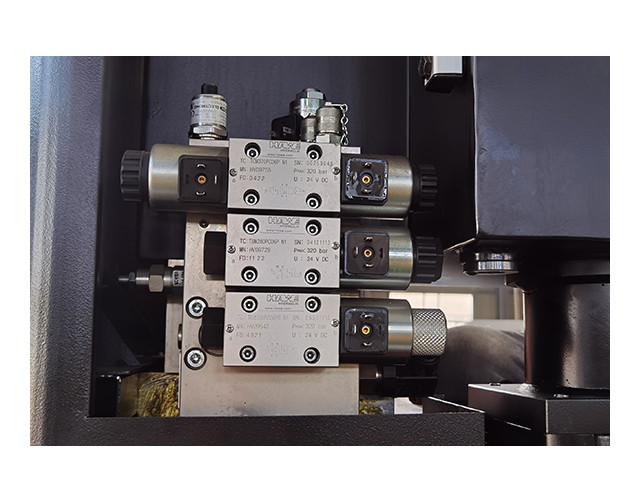

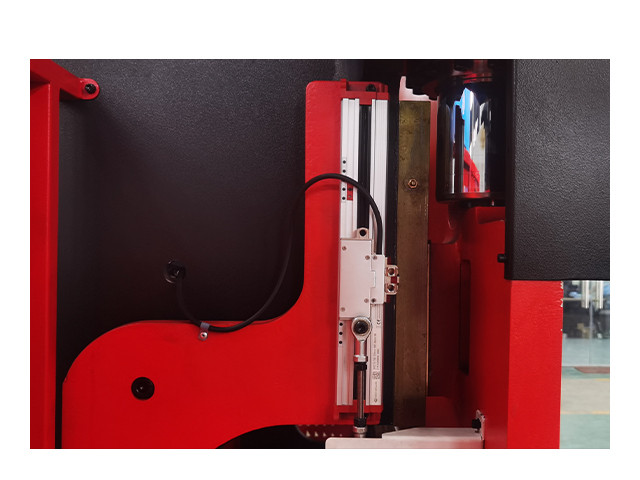

ePrAX control is a newly developed electro-hydraulic control scheme, whichcombines the advantages of two driving technologies: strong hydraulic powerand durability, compact design without external pipelines, and directly installedon the cylinder, cleaner and leak-free.

The system converts electrical signal transmission is carried out between CNC controller into mechanical linear motion. In order to accomplish thismotion, signal transmission is carried out between CNC controller of machinetool and motor drive controller. The synchronous cylinder controls thefollowing work and fast running according to the preset working curve .

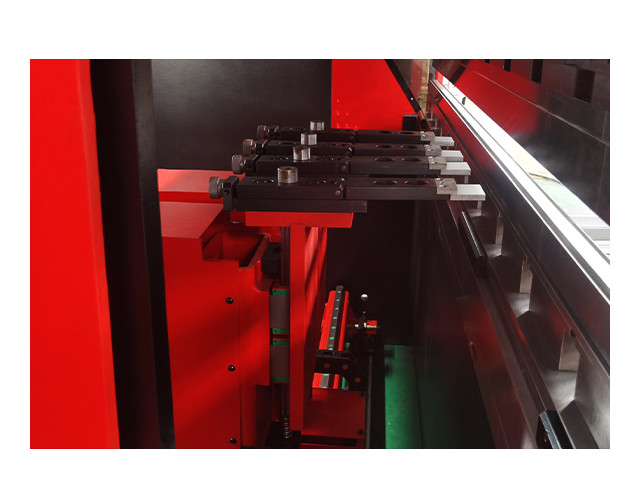

Avariable speed servo pump unit is used to drive and control the position ofthe bending tool and the bending force in the bending process.

Model

WF67K-series | Nominal

Pressure

(mm) | Bending

Length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | SlipperStroke(mm) | Max

Opening

Height

(mm) | Main

motor

(KW) | Travel

(mm) | Weight

(Kg) |

40T/1600 | 400 | 1600 | 1260 | 300 | 150 | 420 | 5.5 | 500 | 3800 |

63T/2500 | 630 | 2500 | 2000 | 300 | 150 | 420 | 5.5 | 500 | 4800 |

80T/2500 | 800 | 2500 | 2000 | 350 | 200 | 480 | 7.5 | 600 | 5700 |

|

100T/3200

|

1000

|

3200

|

2700 | 400 |

200/250

|

480/520 | 7.5 | 600 | 8500 |

|

100T/4000

|

1000

|

4000

|

3600 | 400 |

200/250

|

480/520 | 7.5 | 600 | 9300 |

|

160T/3200

|

1600

|

3200

|

2700 | 400 |

200/250

|

480/520 | 11 | 600 | 9500 |

160T/4000 | 1600 | 4000 | 3600 | 400 | 200/250 | 480/520 | 11 | 600 | 12100 |

|

200T/3200

|

2000

|

3200

|

2700 | 400 |

250

|

530 | 15 | 600 | 11000 |

200T/4000 | 2000 | 4000 | 3600 | 400 | 250 | 530 | 15 | 600 | 13500 |

250T/3200 | 2500 | 3200 | 2700 | 400 | 250 | 530 | 18.5 | 600 | 13000 |

250T/4000 | 2500 | 4000 | 3600 | 400 | 250 | 530 | 18.5 | 600 | 15500 |

250T/5000 | 2500 | 5000 | 4300 | 400 | 250 | 530 | 22 | 600 | 18000 |

300T/3200 | 3000 | 3200 | 2700 | 400 | 300 | 580 | 22 | 600 | 19200 |

300T/4000 | 3000 | 4000 | 3600 | 400 | 300 | 580 | 22 | 600 | 22500 |

400T/4000 | 4000 | 4000 | 3600 | 400 | 320 | 580 | 30 | 600 | 25500 |

400T/5000 | 4000 | 5000 | 4000 | 400 | 320 | 580 | 30 | 600 | 31500 |

500T/4000 | 5000 | 4000 | 3500 | 500 | 320 | 590 | 37 | 600 | 34500 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 320 | 590 | 37 | 800 | 43500 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 320 | 590 | 37 | 800 | 53000 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 320 | 640 | 45 | 800 | 57000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 320 | 640 | 45 | 800 | 68000 |

600T/7000 | 6000 | 7000 | 6000 | 500 | 320 | 640 | 45 | 800 | 79000 |

800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 800 | 55 | 800 | 90000 |

800T/7000 | 8000 | 7000 | 6000 | 600 | 400 | 800 | 55 | 800 | 105000 |

800T/8000 | 8000 | 8000 | 7000 | 600 | 400 | 800 | 55 | 800 | 120000 |

1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 800 | 2x37 | 800 | 100000 |

1000T/8000 | 10000 | 8000 | 6900 | 700 | 400 | 800 | 2x37 | 800 | 130000 |

1000T/10000 | 10000 | 10000 | 8000 | 700 | 400 | 800 | 2x37 | 800 | 150000 |

1200T/6000 | 12000 | 6000 | 4220 | 700 | 400 | 1000 | 2x45 | 1000 | 130000 |

1200T/7000 | 12000 | 7000 | 5220 | 700 | 400 | 1000 | 2x45 | 1000 | 160000 |

1600T/6000 | 16000 | 6000 | 4900 | 700 | 400 | 1000 | 2x55 | 1000 | 150000 |

1600T/7000 | 16000 | 7000 | 5900 | 700 | 400 | 1000 | 2x55 | 1000 | 170000 |

1600T/8000 | 16000 | 8000 | 6900 | 700 | 400 | 1000 | 2x55 | 1000 | 190000 |

1600T/10000 | 16000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 210000 |

2000T/8000 | 20000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | 260000 |

2000T/10000 | 20000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 290000 |

2000T/12000 | 20000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | 320000 |

2000T/14000 | 20000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | 350000 |

3000T/8000 | 30000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/10000 | 30000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/12000 | 30000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/14000 | 30000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

You need a product

You May Like

6YRS Nanjing Rongwin Machinery Technology Ci.,Ltd

- Delivery clauses under the trade mode

- FOB, CIF