WF67K-M series Hybrid CNC Press Brake

group namePress Brake

-

Min Order1 piece

brand nameMeteWorkMas Metal Processing Equipment Experts

modelWF67K-M 80T/2500

-

update timeSat, 02 Nov 2024 09:26:21 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

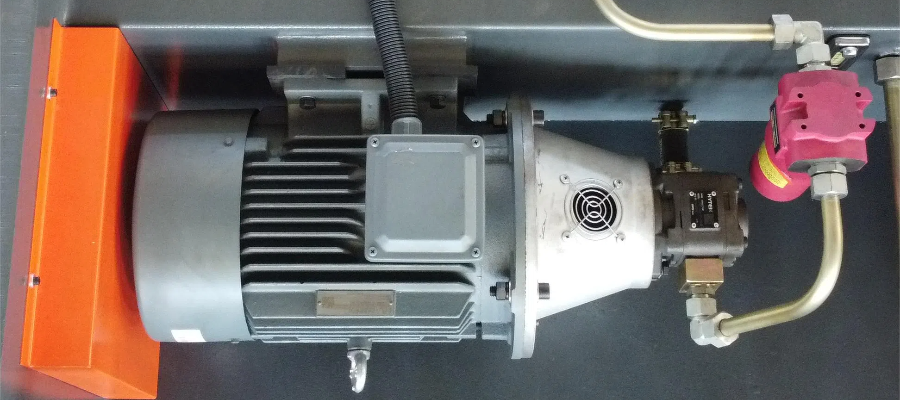

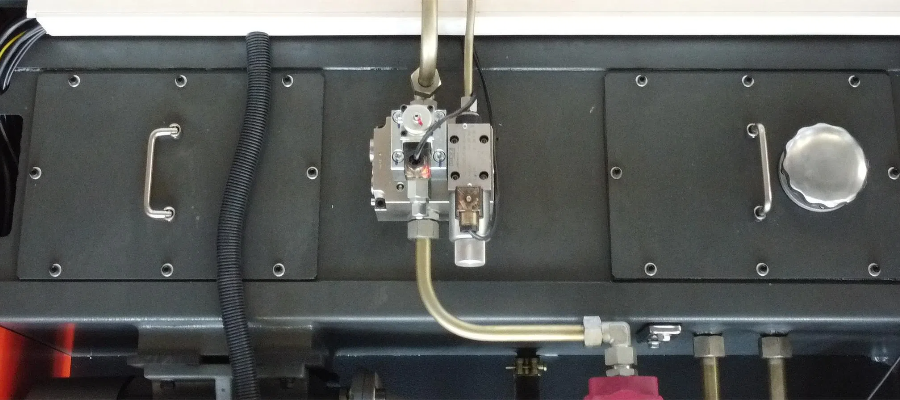

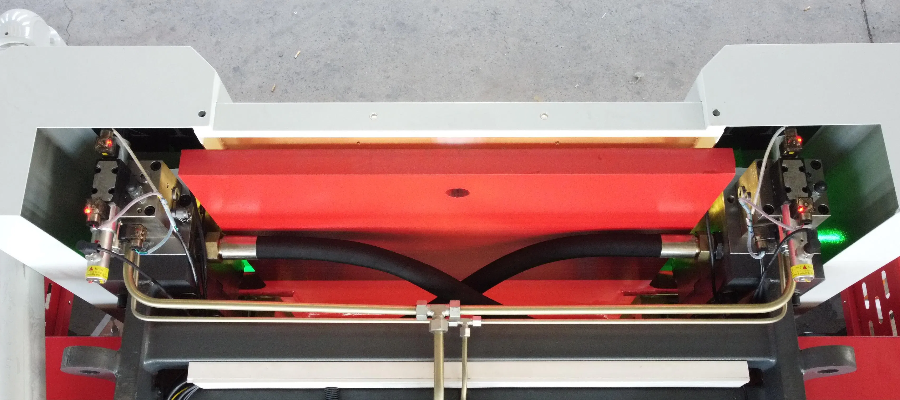

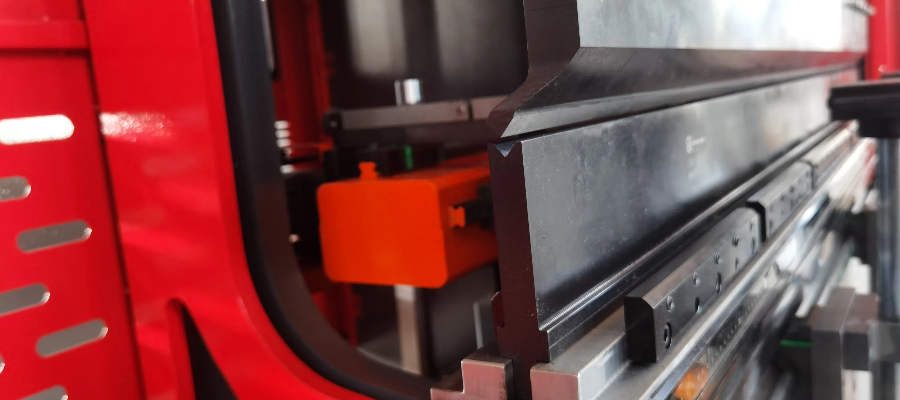

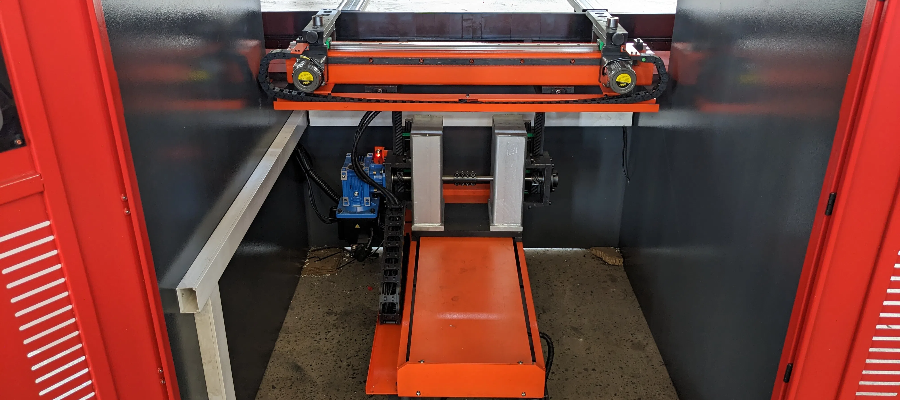

ePrAX control is a newly developed electro-hydraulic control scheme, whichcombines the advantages of two driving technologies: strong hydraulic powerand durability, compact design without external pipelines, and directly installedon the cylinder, cleaner and leak-free.

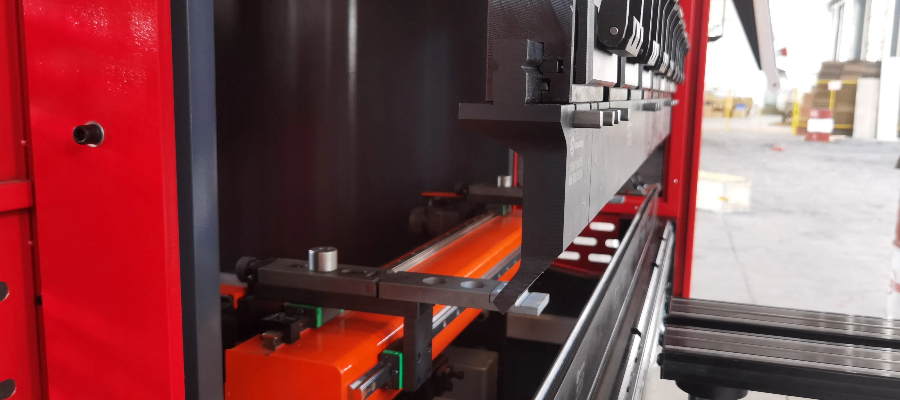

The system converts electrical signal transmission is carried out between CNC controller into mechanical linear motion. In order to accomplish thismotion, signal transmission is carried out between CNC controller of machinetool and motor drive controller. The synchronous cylinder controls thefollowing work and fast running according to the preset working curve .

Avariable speed servo pump unit is used to drive and control the position ofthe bending tool and the bending force in the bending process.

Parameter | Content | ||||

Bending angle: | 0-180 degrees | ||||

Repeat positioning accuracy: | ±0.01mm | ||||

Power requirement: | 380V, 50Hz | ||||

Nominal pressure: | 400 mm - 30000 mm | ||||

Bending length: | 1600 mm - 14000 mm | ||||

Pole distance: | 1260 mm - 11000 mm | ||||

Throat depth: | 300 mm - 700 mm | ||||

Sliding stroke: | 150 mm - 400 mm | ||||

Opening height: | 420 mm - 1000 mm | ||||

Main motor power: | 5.5 KW - 2x55 KW | ||||

Stroke: | 500 mm - 1000 mm | ||||

Minimum weight: | 3800 Kg (maximum model weight depends on specific configuration) | ||||

You need a product

Related Searches

You May Like

6YRS Nanjing Rongwin Machinery Technology Ci.,Ltd

- Delivery clauses under the trade mode

- FOB, CIF