For Pilz PSENopt Series 14 mm Resolution 7 m Sensing Distance 300 mm to 1800 mm Protective Height Advanced Type 4 Light Curtain with Finger Protection Replacement

group namePilz Safety Light Curtains Replacement

-

Min Order1 piece

brand nameDADISICK

modelPSENopt Series | PSEN op4F-A-14-030/1, PSEN op4F-A-14-045/1, PSEN op4F-A-14-060/1, PSEN op4F-A-14-075/1, PSEN op4F-A-14-090/1, PSEN op4F-A-14-105/1, PSEN op4F-A-14-120/1, PSEN op4F-A-14-135/1, PSEN op4F-A-14-150/1, PSEN op4F-A-14-165/1, PSEN op4F-A-14-180/1

payment methodT/T

-

update timeFri, 08 Nov 2024 19:31:06 GMT

Paramtents

Series PSENopt Series

Resolution: 14 mm

Scanning range: 0.2 - 7 m

Protective field height: 300 - 1800 mm

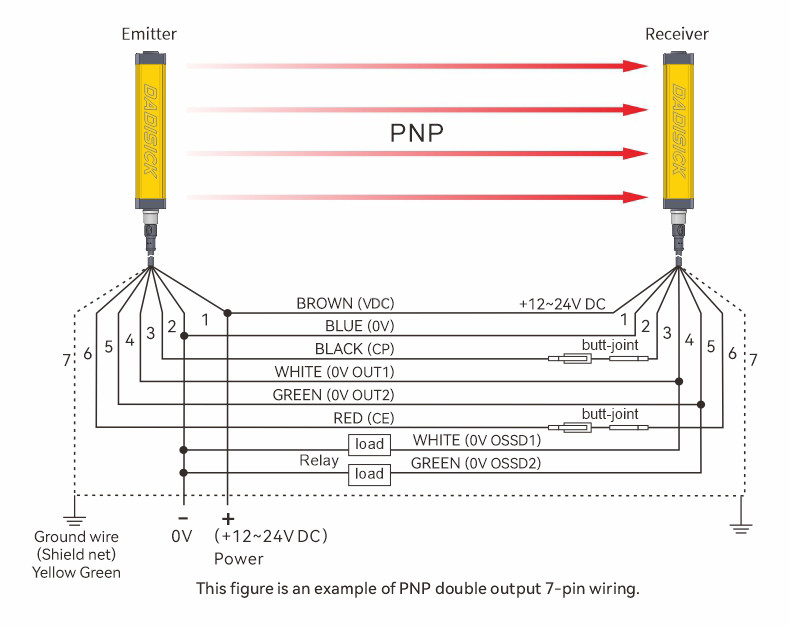

2 Safety outputs (OSSD): 2 PNP

Response time: 15 - 33 ms

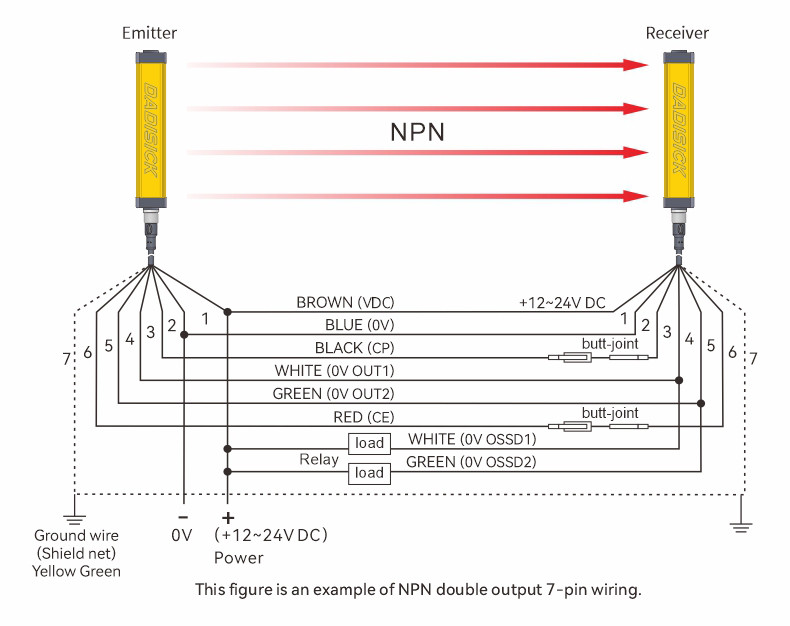

Connection type: M12

Security level: PLe4

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Brand | From network | DADISICK |

|

Models | PSEN op4F-A-14-030/1 | QM30-10-290 2BC | |

PSEN op4F-A-14-045/1 | QM46-10-450 2BC | ||

PSEN op4F-A-14-060/1 | QM60-10-590 2BC | ||

PSEN op4F-A-14-075/1 | QM76-10-750 2BC |

||

PSEN op4F-A-14-090/1 |

QM90-10-890 2BC | ||

PSEN op4F-A-14-105/1 | QM106-10-1050 2BC |

||

PSEN op4F-A-14-120/1 | QM120-10-1190 2BC | ||

PSEN op4F-A-14-135/1 | QM136-10-1350 2BC | ||

PSEN op4F-A-14-150/1 | QM150-10-1490 2BC | ||

PSEN op4F-A-14-165/1 | QM166-10-1650 2BC | ||

PSEN op4F-A-14-180/1 | QM180-10-1790 2BC | ||

Beam spacing | 14 mm | 10 mm | |

Protected altitude | 300 mm, 450 mm, 600 mm, 750 mm, 900 mm, 1050 mm, 1200 mm, 1350 mm, 1500 mm, 1650 mm, 1800 mm | 290 mm, 450 mm, 590 mm, 750 mm, 890 mm, 1050 mm, 1190 mm, 1350 mm, 1490 mm, 1650 mm, 1790 mm | |

Scanning range | 0.2 - 7 m | 0.3 - 10 m | |

Response time | 15 ms - 33 ms | ≤15 ms | |

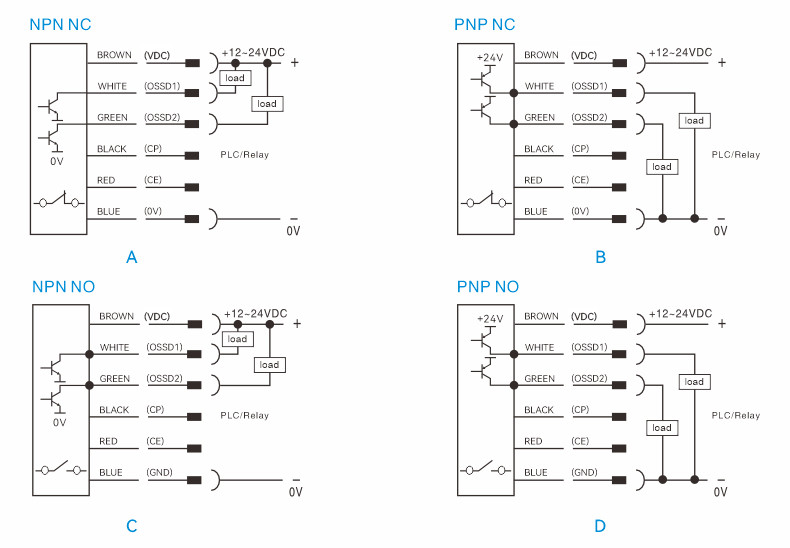

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

Connector | M12 | M12 | |

Housing cross-section | 40.8 mm x 35 mm | 36 mm x 36 mm | |

Safety Certificate | CE, cULus, TÜV, EAC | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

You need a product

You May Like

6YRS Dongguan Dadi Electronic Technology Co., Ltd