MLD 500 Series 500 mm Resolution 50 m Sensing Distance 500 mm Protective Height Multiple light beam safety devices Replacement

group nameMLD 500 Series Multiple light beam safety devices Replacement

-

Min Order1 piece

brand nameDADISICK

modelMLD 500 Series | MLD500-T2, MLD510-R2, MLD500-T2/A, MLD510-R2/A, MLD500-T2/A, MLD510-R2E/A, MLD500-T2/A, MLD510-R2M/A, MLD500-T2L/A, MLD510-R2LM/A, MLD500-T2L, MLD510-R2L, MLD500-T2L/A, MLD510-R2L/A, MLD500-T2L/A, MLD510-R2LE/A, MLD500-T2, MLD520-R2, MLD500-T2, MLD520-R2M, MLD500-T2L, MLD520-R2LM, MLD500-T2L, MLD520-R2L, MLD500-T2, MLD530-R2, MLD500-T2, MLD530-R2M, MLD500-T2L, MLD530-R2LM, MLD500-T2L, MLD530-R2L, MLD500-T2, MLD535-R2, MLD500-T2, MLD535-R2M, MLD500-T2L, MLD535-R2LM, MLD500-T2L, MLD535-R2L

payment methodT/T

-

update timeWed, 26 Jun 2024 22:52:03 GMT

Paramtents

Series: MLD 500 Series

Resolution: 500 mm

Scanning range: 0.5 - 50 m

Protective field height: 500 mm

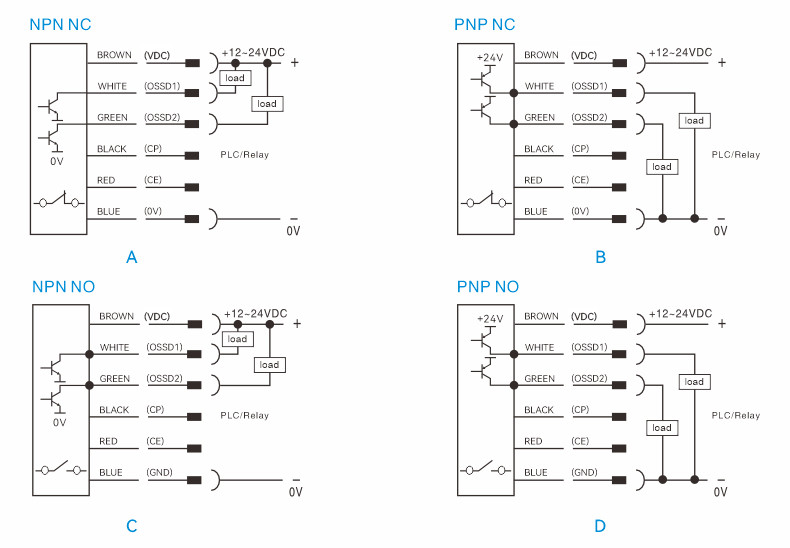

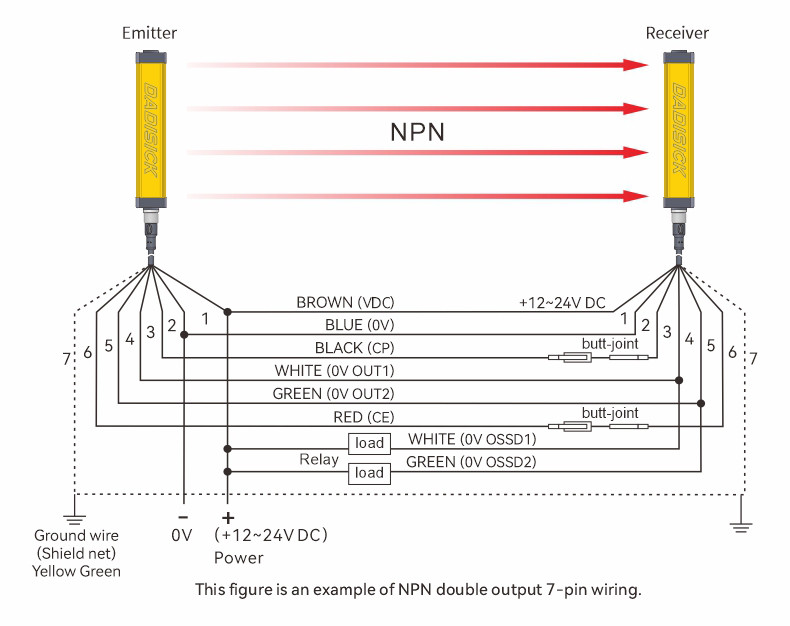

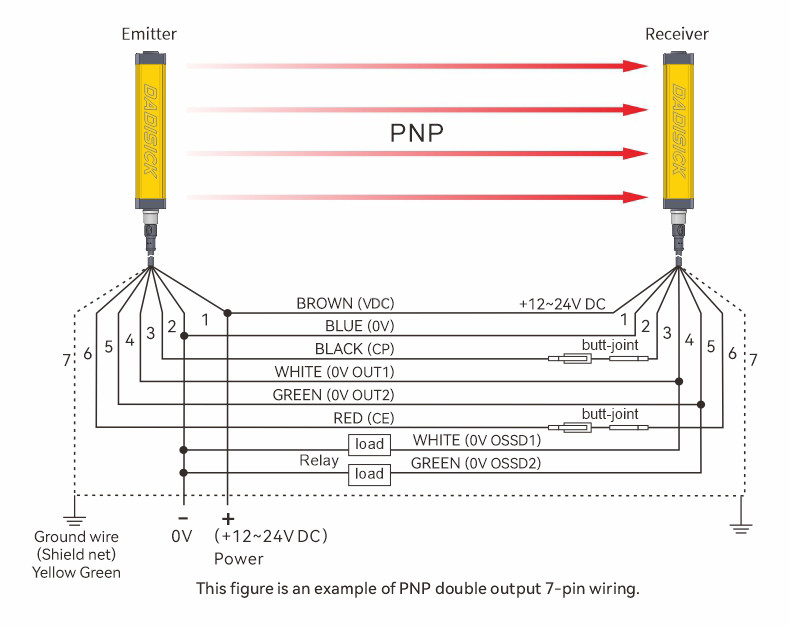

2 Safety outputs (OSSD): 2 PNP

Response time: 25 - 50 ms

Connection type: M12

security level: PLe4

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Brand | Transmitter | Receiver | DADISICK |

|

|

Models

|

MLD500-T2 | MLD510-R2 | QT04-200-600 2BH |

|

MLD500-T2/A |

MLD510-R2/A | QT04-200-600 2BH | ||

MLD500-T2/A | MLD510-R2E/A | QT04-200-600 2BH |

||

MLD500-T2/A | MLD510-R2M/A | QT04-200-600 2BH | ||

MLD500-T2L/A | MLD510-R2LM/A | QT04-200-600 2BH | ||

MLD500-T2L | MLD510-R2L | QT04-200-600 2BH | ||

MLD500-T2L/A | MLD510-R2L/A | QT04-200-600 2BH | ||

MLD500-T2L/A | MLD510-R2LE/A | QT04-200-600 2BH | ||

MLD500-T2 | MLD520-R2 | QT04-200-600 2BH | ||

MLD500-T2 | MLD520-R2M | QT04-200-600 2BH | ||

MLD500-T2L | MLD520-R2LM | QT04-200-600 2BH | ||

MLD500-T2L | MLD520-R2L | QT04-200-600 2BH | ||

MLD500-T2 | MLD530-R2 | QT04-200-600 2BH | ||

MLD500-T2 | MLD530-R2M | QT04-200-600 2BH | ||

MLD500-T2L | MLD530-R2LM | QT04-200-600 2BH | ||

MLD500-T2L | MLD530-R2L | QT04-200-600 2BH | ||

MLD500-T2 | MLD535-R2 | QT04-200-600 2BH | ||

MLD500-T2 | MLD535-R2M | QT04-200-600 2BH | ||

MLD500-T2L | MLD535-R2LM | QT04-200-600 2BH | ||

MLD500-T2L | MLD535-R2L | QT04-200-600 2BH | ||

Beam spacing | 500 mm | 200 mm | ||

Protected altitude | 500 mm | 600 mm | ||

Scanning range | 0.5 - 50 m | 0.3 - 45 m | ||

Response time | 25 - 50 ms | ≤15 ms | ||

Output method | 2 PNP | 2 PNP | ||

Reliability and durability | IP67 | IP65 | ||

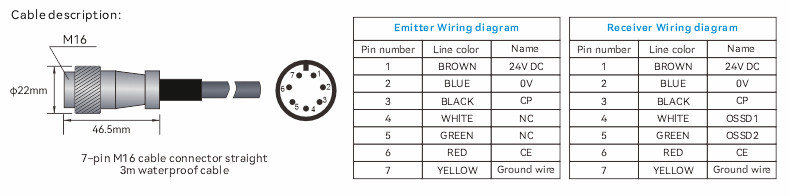

Connector | M12 | M16 | ||

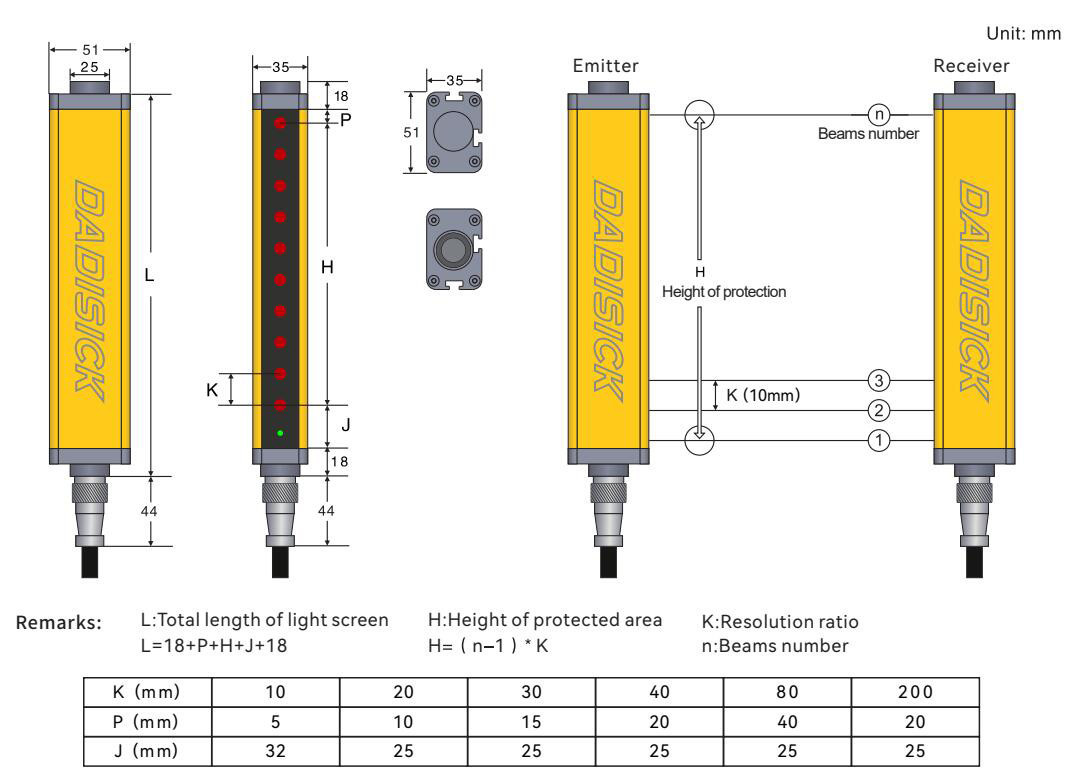

Housing cross-section | 64.7 mm x 52 mm | 51 mm x 35 mm | ||

Safety Certificate | TÜV Süd, c CSA US, c TÜV NRTL US | TÜV, UL, CE, RoHS, GB | ||

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | ||||

You need a product

You May Like

6YRS Dongguan Dadi Electronic Technology Co., Ltd