EZ-SCREEN LS Basic Series Type 4 Safety Light Curtain Replacement 23 mm Resolution | 12 m Operating Range | 350 mm to 1330 mm Protective Height

group nameTurck Safety Light Curtains Replacement

-

Min Order1 piece

brand nameDADISICK

modelEZ-SCREEN LS Basic Series | SLLVP23-350, SLLVP23-420, SLLVP23-630, SLLVP23-910, SLLVP23-1050, SLLVP23-1190, SLLVP23-1260, SLLVP23-1330, SLLVR23-350, SLLVR23-420, SLLVR23-630, SLLVR23-910, SLLVR23-1050, SLLVR23-1190, SLLVR23-1260, SLLVR23-1330, SLLVE23-350, SLLVE23-420, SLLVE23-630, SLLVE23-910, SLLVE23-1050, SLLVE23-1190, SLLVE23-1260, SLLVE23-1330

payment methodT/T

-

update timeFri, 08 Nov 2024 14:09:06 GMT

Paramtents

Series: EZ-SCREEN LS Basic Series

Resolution: 23 mm

Scanning range: 0.1 m - 12 m

Protective field height: 350 mm - 1330 mm

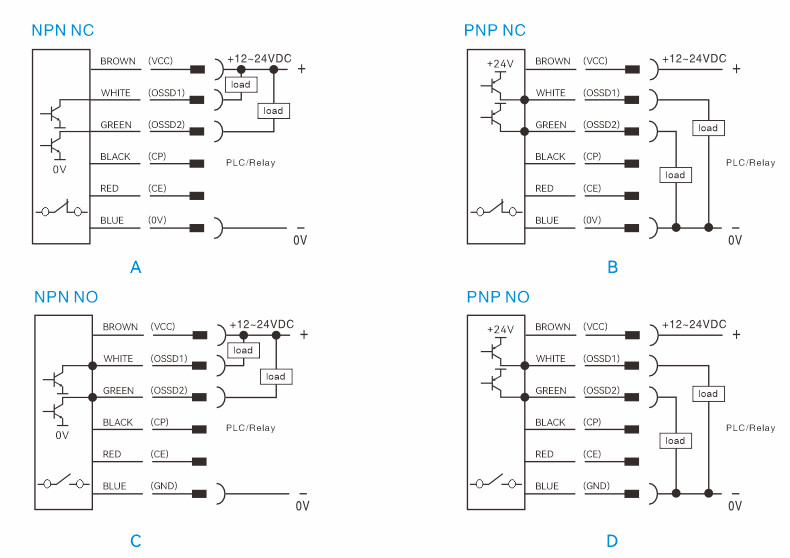

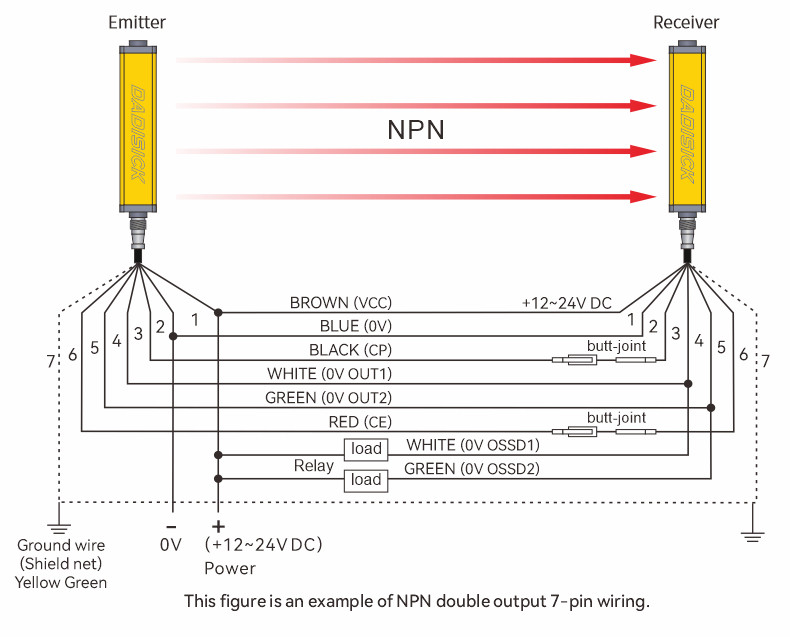

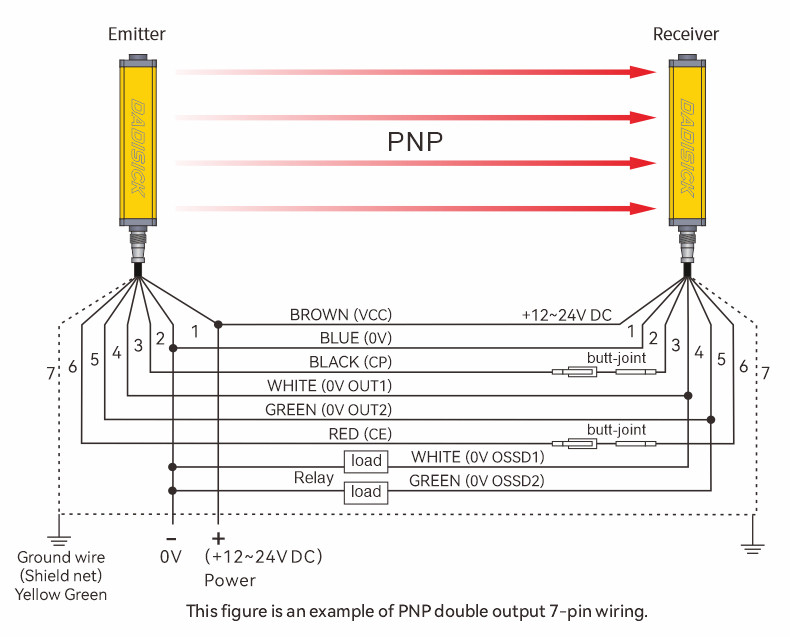

2 Safety outputs (OSSD): 2 PNP

Response time: 9.1 ms - 20.9 ms

Connection type: M12

Security level: PLe4

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Pair | Receiver | Emitter | DADISICK |

SLLVP23-350 | SLLVR23-350 |

SLLVE23-350 | QT18-20-340-2BD |

SLLVP23-420 | SLLVR23-420 | SLLVE23-420 |

QT22-20-420-2BD |

SLLVP23-630 | SLLVR23-630 | SLLVE23-630 | QT32-20-620-2BD |

SLLVP23-910 | SLLVR23-910 | SLLVE23-910 | QT46-20-900-2BD |

SLLVP23-1050 | SLLVR23-1050 | SLLVE23-1050 | QT54-20-1060-2BD |

SLLVP23-1190 | SLLVR23-1190 | SLLVE23-1190 | QT60-20-1180-2BD |

SLLVP23-1260 | SLLVR23-1260 | SLLVE23-1260 | QT64-20-1260-2BD |

SLLVP23-1330 | SLLVR23-1330 | SLLVE23-1330 | QT68-20-1340-2BD |

Beam spacing | 23 mm | 20 mm | |

Protected altitude | 350 mm, 420 mm, 630 mm, 910 mm, 1050 mm, 1190 mm, 1260 mm, 1330 mm | 340 mm, 420 mm, 620 mm, 900 mm, 1060 mm, 1180 mm, 1260 mm, 1340 mm | |

Scanning range | 0.1 m - 12 m | 0.3 m - 15 m | |

Response time | 9.1 ms - 20.9 ms | ≤15 ms | |

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 / IP67 | IP65 | |

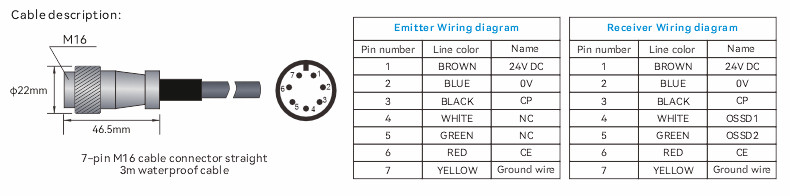

Connector | M12 | M16 | |

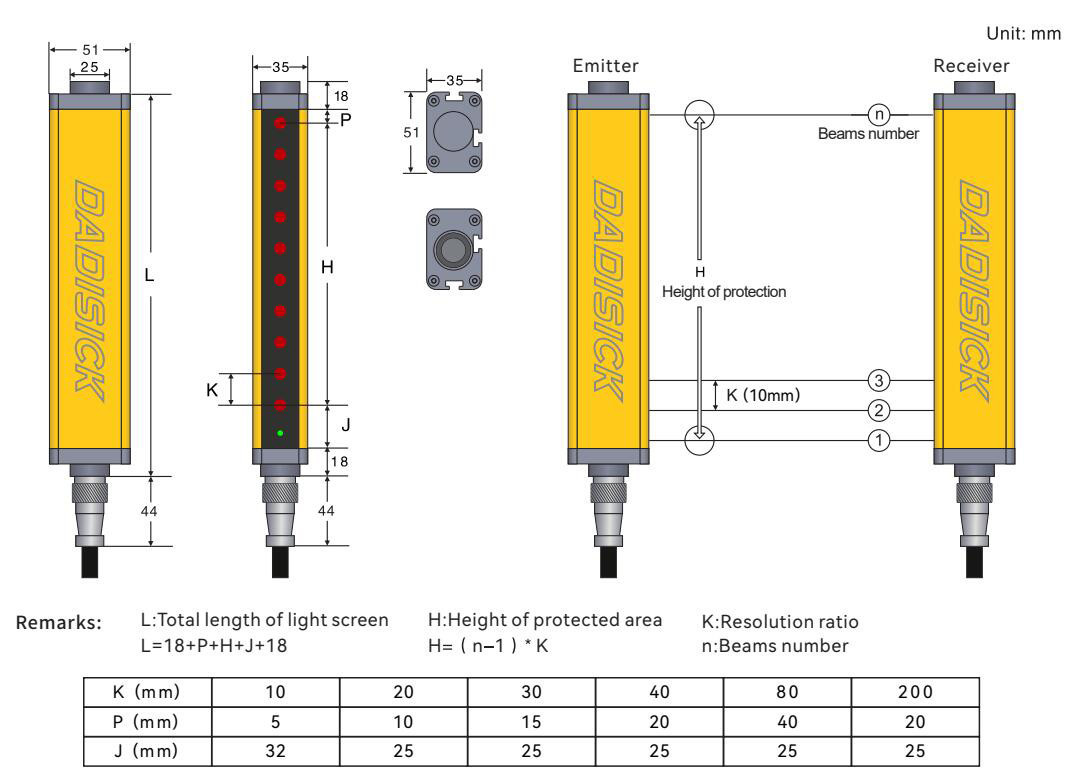

Housing cross-section | 45 mm × 36 mm | 35 mm × 51 mm | |

Safety Certificate | cULus, CE | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

You need a product

You May Like

6YRS Dongguan Dadi Electronic Technology Co., Ltd