OEM & ODM Automotive Silicone Parts | Versatile Heat, Cold & Weather Resistant Solutions for Enhanced Safety and Eco-Friendliness | Custom Liquid Silicone Overmolding & Rubber Overmolding Services

group nameAutomotive Silicone Overmolding

-

Min Order1 piece

brand nameSiliconePlus | Silicone OverMolding Manufacturing

payment methodT/T, Paypal

-

update timeTue, 05 Nov 2024 11:50:02 GMT

Paramtents

Product name Car silicone shock pad

Waterproof grade IP68

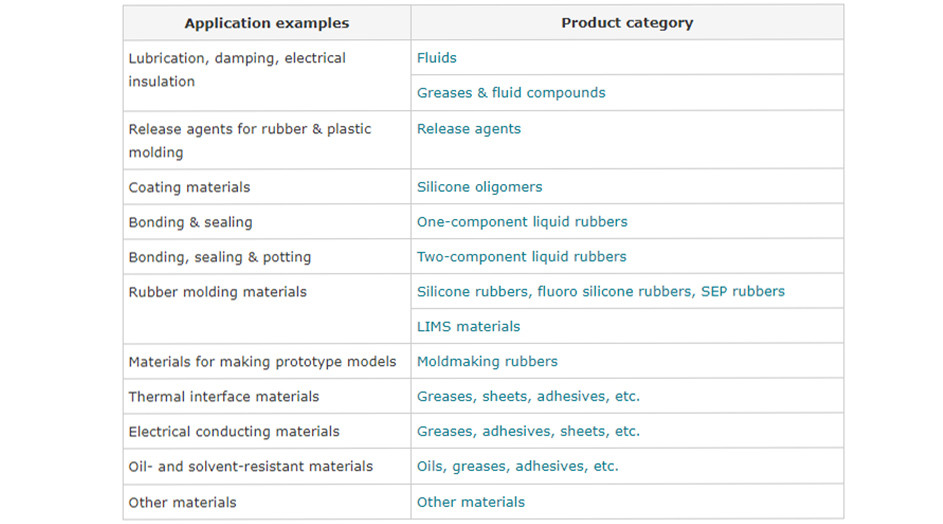

Product Material Metal + liquid silicone

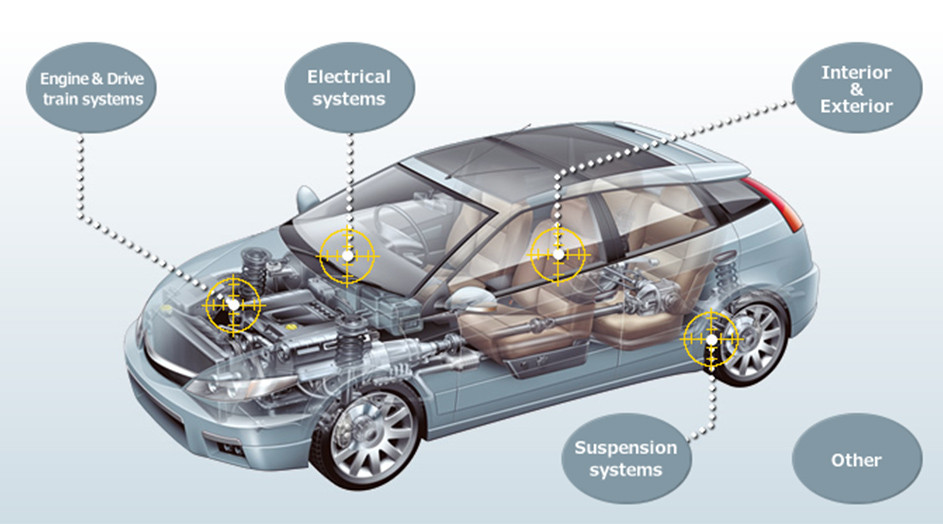

Applications Automotive Industry

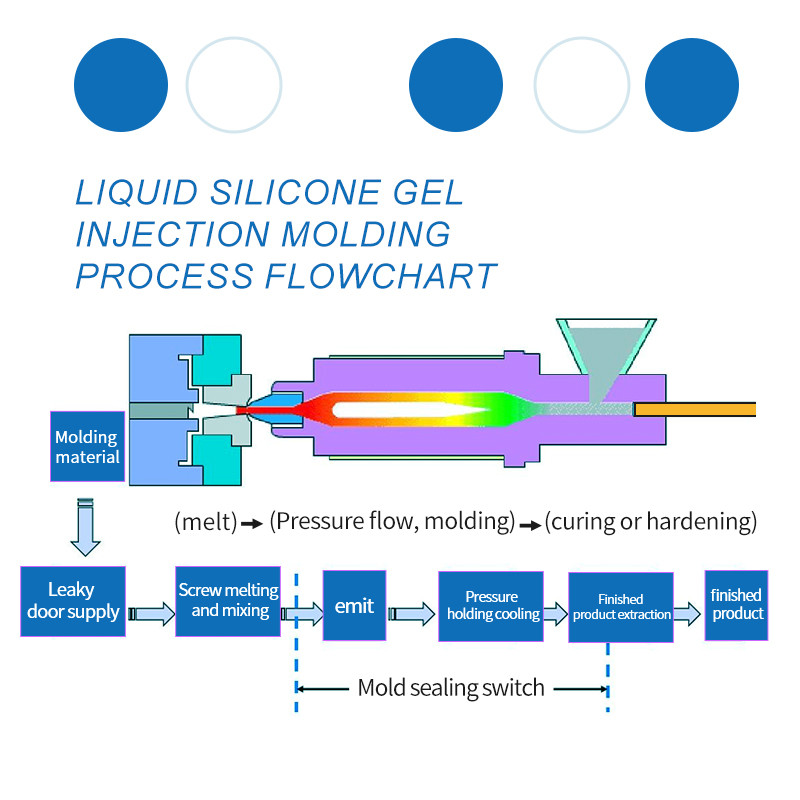

Product process LSR one-piece molding

Processing accuracy 0.003mm

Product size control accuracy 士0.03mm

Packging & Delivery

Size32cm x 25cm x 36cm

Weight0.65kg / piece

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian (shenzhen,guangdong, china), Shekou (shenzhen,guangdong, china)

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash, Escrow