1. Unstable waterproof effectPain point: The waterproof encapsulation effect of the card tray is not ideal, resulting in the inability to effectively protect the inside of the SIM card tray when the mobile phone is exposed to water, which in turn affects the overall waterproof performance of the mobile phone.

Solution: Siliconeplus uses high-precision liquid silicone encapsulation technology to ensure that the waterproof sealing of each card tray interface meets the IP67 or IP68 standard, and through strict testing, ensures the stable protection effect of the product in a water environment.

2. Insufficient adhesion between silicone and metal card tray

Pain point: In the card tray encapsulation product, the adhesion between silicone and the metal substrate is not strong enough, resulting in the easy fall-off of the encapsulated part, affecting the waterproof effect.

Solution: Siliconeplus uses professional surface treatment and silicone bonding technology to ensure that the silicone adheres firmly to the metal card tray, effectively preventing degumming and enhancing the overall durability and protection of the card tray.

3. Dimensional accuracy and batch consistency issues

Pain point: Customers require high-precision card tray products to ensure precise matching with the mobile phone card slot. However, many suppliers have difficulty in ensuring dimensional consistency in mass production, which may cause the product to jam or fail to install during assembly.

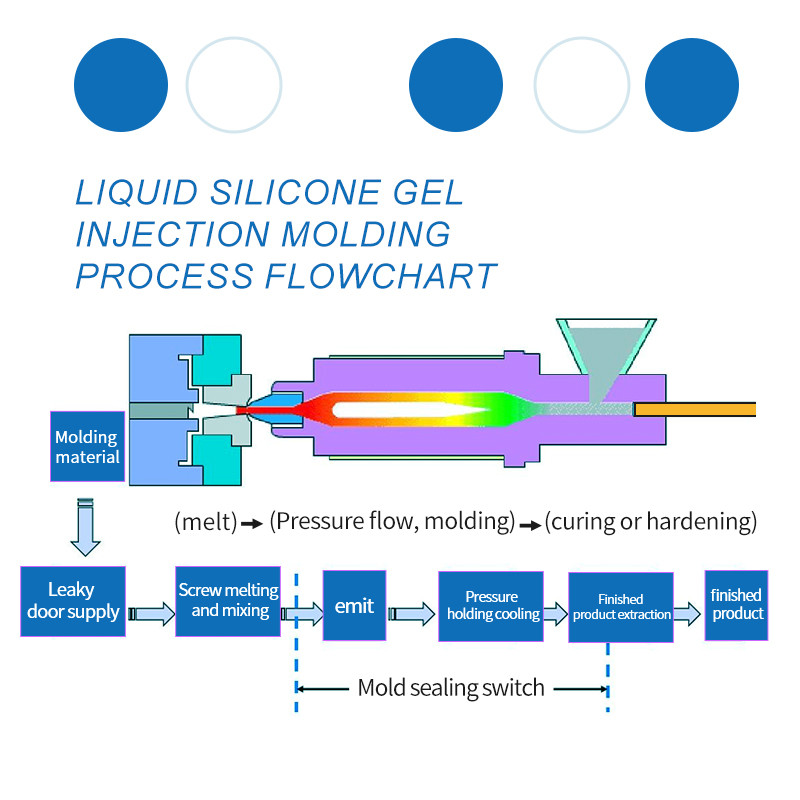

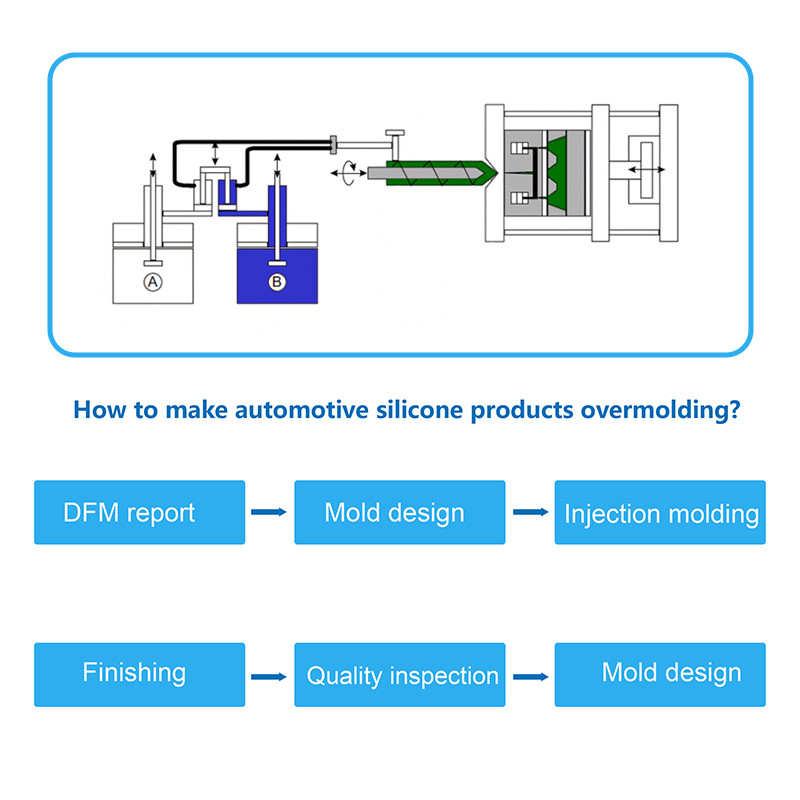

Solution: Siliconeplus uses its own mold room and precision mold design, combined with advanced injection molding technology, to ensure the dimensional accuracy and batch consistency of the card tray encapsulated products, avoiding the impact of dimensional deviation on assembly and use.

4. Surface defects caused by demolding difficulties

Pain point: The card tray is prone to sticking during the demolding process, resulting in surface defects or damage, affecting the appearance and performance of the product.

Solution: Siliconeplus uses optimized mold design and advanced demolding technology to ensure that the card tray can be demolded smoothly, keep the product surface smooth, and ensure high-quality appearance and consistency.

5. Waterproof encapsulation affects the ease of use of the card tray

Pain point: Too thick or uneven waterproof encapsulation may make it difficult to insert and remove the card tray in the mobile phone, affecting the user experience.

Solution: Siliconeplus uses precision injection molding to ensure that the thickness of the encapsulation layer is uniform and moderate, so that the card tray can be easily inserted and removed, taking into account both waterproof performance and user convenience.

6. Improper material selection affects durability

Pain point: Some card tray encapsulation products on the market use inferior materials, which causes aging or cracking in high temperature, low temperature or humid environment, affecting the service life.

Solution: Siliconeplus uses high-quality liquid silicone materials with excellent high temperature resistance, low temperature resistance and anti-aging properties to ensure that the product maintains good performance and durability under different environmental conditions.

7. Waterproof encapsulation affects the conductivity of metal

Pain point: The metal part of the card tray usually needs to have a certain conductivity. If the encapsulation is not handled properly, the conductivity may be affected.

Solution: Siliconeplus uses precise encapsulation technology to ensure that the metal parts are effectively protected during the encapsulation process, ensuring that the metal part of the card tray still has good conductivity after waterproofing.

8. Unstable delivery cycle

Pain point: Customers have high requirements for delivery cycle, especially in the fierce competition in the mobile phone accessories market, and fast delivery is crucial to maintaining market competitiveness. Many suppliers find it difficult to ensure stable delivery time.

Solution: Siliconeplus shortens the time from design to production through its own mold room and integrated production capacity, and can complete mass production within 3-4 weeks, ensuring timely delivery, helping customers seize the initiative in the fiercely competitive market.

With its professional technology and production experience, Siliconeplus can effectively solve the pain points encountered by customers in the waterproof encapsulation of hardware mobile phone card trays, provide high-quality and reliable products, and help customers improve their market competitiveness.