1. Compatibility of silicone masks and LED componentsPain point: LED masks need to combine silicone with precision electronic components. If the encapsulation is not accurate enough, it may affect the LED light transmission and user experience. However, many manufacturers on the market cannot achieve high-precision integration of silicone and electronic components.

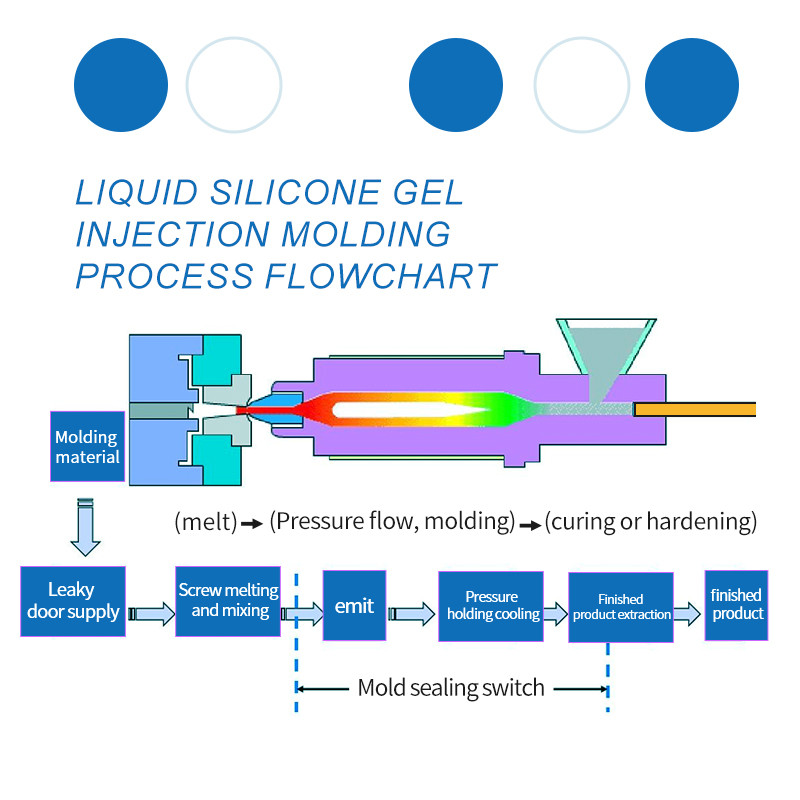

Solution: Siliconeplus uses precision liquid silicone injection molding technology to ensure the perfect combination of silicone and LED components, ensuring the stability of light transmission effect and overall performance.

2. Safety and comfort of materials

Pain point: Beauty masks need to be in contact with facial skin for a long time. Customers have high requirements for the safety and comfort of materials. Many mask materials may cause skin allergies or discomfort.

Solution: Siliconeplus uses medical-grade liquid silicone, which is non-toxic, non-allergenic, soft and comfortable, ensuring that users experience comfort during use without any skin irritation, meeting high safety requirements.

3. Product design and adaptability to wearing

Pain point: Different consumers have different face shapes. Many masks cannot fit the face well, resulting in uncomfortable wearing or affecting the coverage of LED light, thereby reducing product effectiveness.

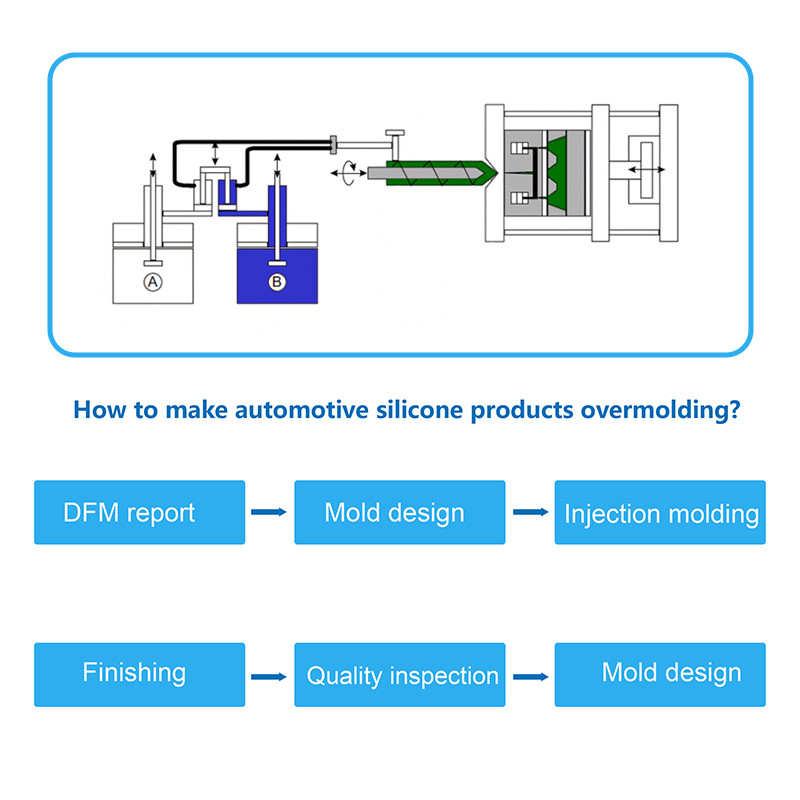

Solution: Siliconeplus has its own mold room, which can customize molds according to the specific design requirements of customers, ensure the fit and comfort of the mask, provide designs suitable for different face shapes, and ensure that the light covers the face evenly.

4. The bonding between silicone and electronic components is not strong

Pain point: The silicone of the LED mask is not firmly bonded to the electronic components, which can easily cause the electronic components to fall off or have poor contact during use, affecting the service life of the product and user experience.

Solution: Siliconeplus uses advanced bonding technology and fine encapsulation technology to ensure that silicone and electronic components are firmly combined to prevent falling off and poor contact, and improve the service life and safety of the product.

5. Production consistency and quality control

Pain point: In the mass production of LED silicone beauty mask products, the consistency and quality of the products are difficult to guarantee, which is easy to cause market complaints or affect the brand reputation.

Solution: Siliconeplus uses a strict quality control system and precise mold design to ensure the quality consistency of each product in mass production, whether it is the product appearance or internal function, it can maintain the same high quality.

6. Unsatisfactory light-guiding effect

Pain point: The main function of LED masks is to provide beauty through phototherapy, and the light transmittance of silicone is crucial to the overall effect. Some masks on the market have uneven light transmission due to improper selection of silicone materials, which affects the effect.

Solution: Siliconeplus uses liquid silicone materials with high light transmittance to ensure that LED light can be evenly transmitted, thereby achieving the best beauty effect and enhancing user experience.

7. Inconvenient cleaning and maintenance

Pain point: LED silicone beauty masks need to be cleaned frequently, while some products on the market are inconvenient to clean due to design or material problems, which easily breeds bacteria and affects safety in use.

Solution: The silicone mask material designed by Siliconeplus is easy to clean, durable and anti-aging. It can be cleaned repeatedly without affecting product quality and performance, ensuring safety and convenience for users.

8. Long delivery cycle

Pain point: The production process of LED silicone beauty masks is relatively complicated, especially the combination of silicone and electronic components. The delivery cycle of many suppliers is too long, which affects the speed of market launch.

Solution: Siliconeplus has its own mold room and production line, which can quickly complete all processes from design to production, shorten the production cycle, ensure on-time delivery, and help customers seize market opportunities.

Through comprehensive solutions for these pain points, Siliconeplus, with its advanced liquid silicone technology, professional engineering team and the advantages of its own mold room, can provide customers with high-quality, stable and reliable LED liquid silicone beauty mask products, helping customers effectively respond to market demand and improve product performance and user experience.