Durable Silicone Encased LED Strip for Flexible Lighting Solutions Custom Silicone Overmolded FPC for Waterproof and Flexible Solutions

group name3C Electronics Silicone Overmolding

-

Min Order1 piece

brand nameSiliconePlus | Silicone OverMolding Manufacturing

payment methodT/T, Paypal

-

update timeFri, 01 Nov 2024 11:34:47 GMT

Paramtents

Product name Waterproof silicone LED strip lights

Waterproof grade IP68

Product Material FPC + liquid silicone+LED

Applications Electronic waterproof

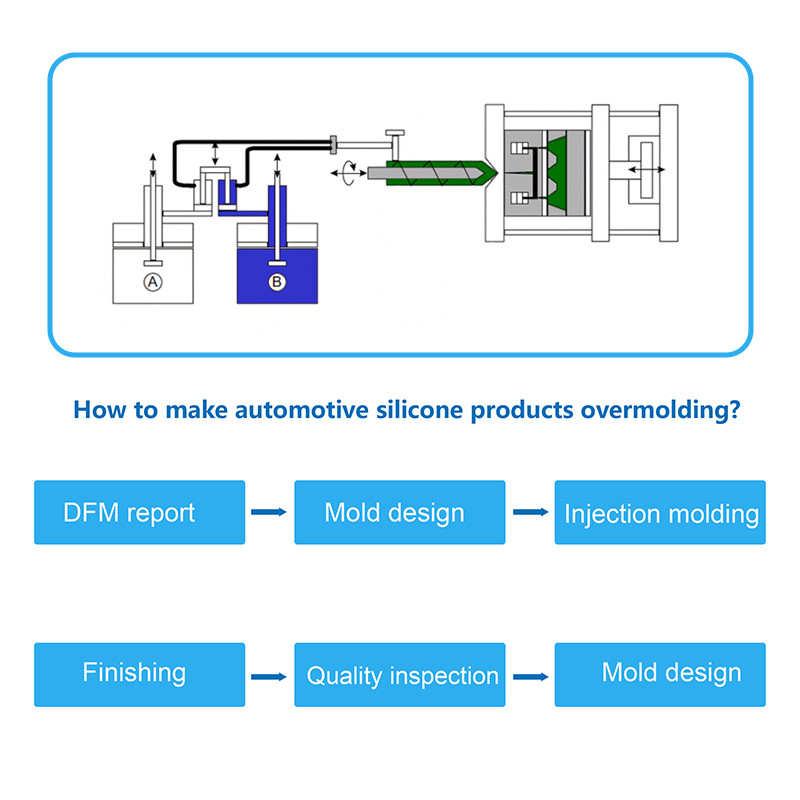

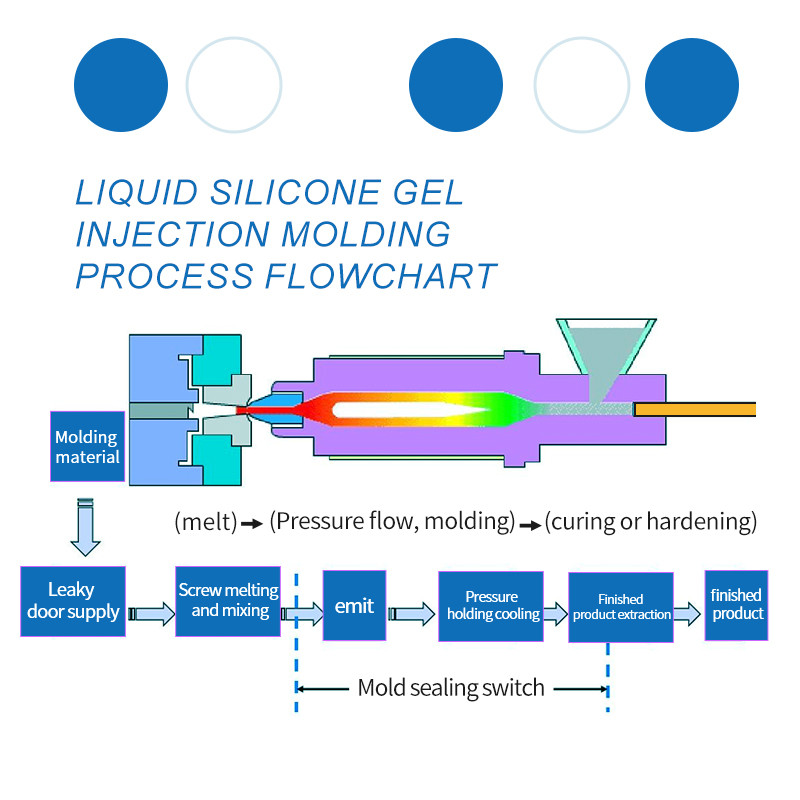

Product process Liquid Silicone Injection Molding

Processing accuracy 0.003mm

Product size control accuracy 士0.03mm

MOQ 100

Packging & Delivery

Size32cm x 25cm x 36cm

Weight0.65kg / piece

Min Order1 piece

Briefing

Detailed

Liquid silicone injection molding

|

Attribute

|

Description

|

||

|

Material Type

|

Medical-grade/industrial-grade silicone, waterproof, corrosion-resistant, high-temperature resistant

|

||

|

Size Options

|

Supports customization, available in different sizes for various FPC and LED strip requirements

|

||

|

Color

|

Standard colors available, supports brand customization

|

||

Manufacturing Process | Liquid Silicone Injection Molding (LSR Injection Molding) | ||

Application Industries | Electronics, lighting, automotive, outdoor equipment, etc. | ||

Environmental Certification | Complies with RoHS, REACH, and other environmental standards | ||

You need a product

You May Like

- Nearest port for product export

- Yantian (shenzhen,guangdong, china), Shekou (shenzhen,guangdong, china)

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash, Escrow