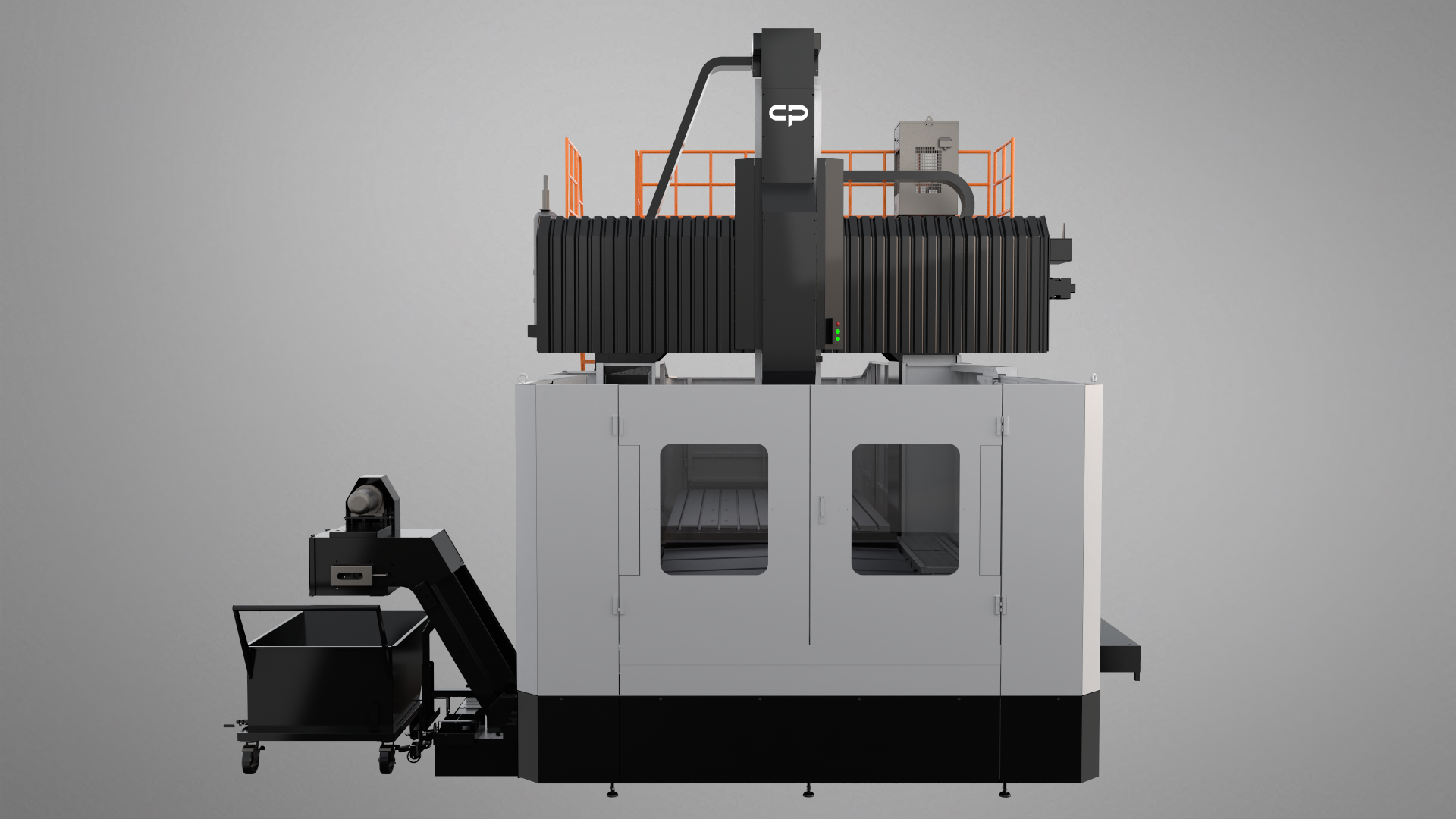

SP1840 Belt spindle T type ram

group nameClassic T Type Ram Series

-

Min Order1 piece

brand nameZOPO INTELLIGENT EQUIPMENT MACHINING CENTER OEM

modelSP1840

-

update timeFri, 01 Nov 2024 17:37:37 GMT

Paramtents

Brand ZOPOCNC

CNCsystem FANUC/SIEMENS/MITSUBIHSI

Spindle Belt spindle

Control Semi-closed loop control

Packging & Delivery

Min Order1 piece

Briefing

Detailed

SP1840

Classic T type ram series

The first choice for processing small molds, mechanical parts, petroleum, aviation, rail transportation and other industries

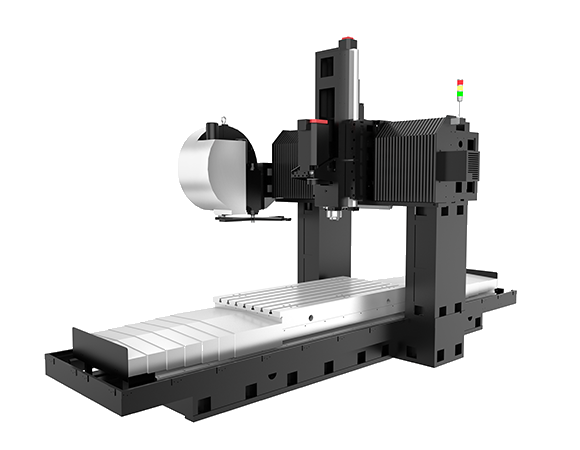

4200/1850/1000mm

TRAVEL

1800x4000mm

WORKTABLE

6000rpm

SPINDLE SPEED

10/10/10m/min

RAPID FEED RATE

- Model

- Appearance

- Characteristics

- Parameters

- Contact Us

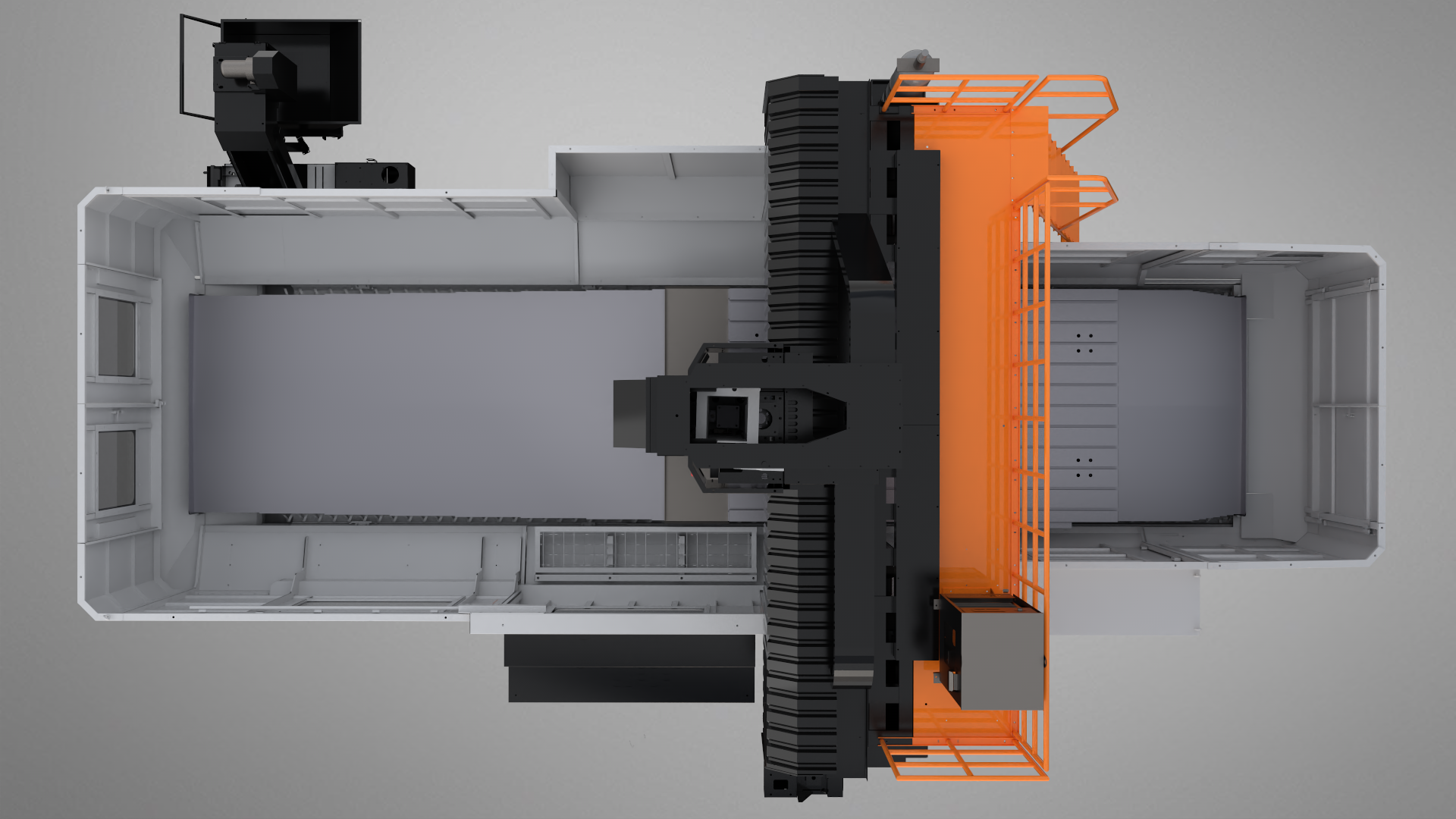

Serialized and modular design

High precision and high stability structural design

- Ram:Optimal central symmetrical spindle box design; hard rail with extra-large cross-section and high rigidity; overall rigidity increased by 20%.

- Worktable:The worktable is hollowed out, and the moving parts are lightweight, which improves the response speed of the worktable.

- Machine body:One-piece casting bed and internal reinforcement rib design ensure stability and high rigidity; simplify assembly process, reduce assembly errors caused by personnel, and improve machine tool stability.

- Beam:The optimal stepped beam and saddle design shifts the overall center of gravity of the spindle box backwards, increasing the machining rigidity.

Easier to use and more powerful control system

- Selection of energy-efficient processing modes

- Tool management function

- Broken tool detection function

- Troubleshooting guide function

- Super powerful human-computer interaction interface.

Working range

- X/Y/Z axis travel

- 4200/1850/1000mm

- Distance between two columns

- 2000mm

- Distance from table surface to spindle nose

- 260-1260mm

Worktable

- Worktable size

- 1800x4000mm

- T-slot size

- 11-22*160mm

- Max. load bearing of worktable

- 14000kg

Spindle

- Spindle hole taper

- BT50

- Main motor power

- 15/18.5(Wide area)KW

- Spindle speed

- 6000(Belt)rpm

Feed

- Max. feed speed

- 8000mm/min

- Rapid feed rate

- 10/10/10m/min

Accuracy

- Positioning accuracy

- 0.030/0.018/0.020mm

- Re-positioning accuracy

- 0.014/0.012/0.008mm

Machine

- Machine dimension

- 10400*5800*5500mm

- Machine weight

- 35500kg

You need a product

Related Searches

You May Like

6YRS ZOPO Intelligent Equipment CO., Ltd.