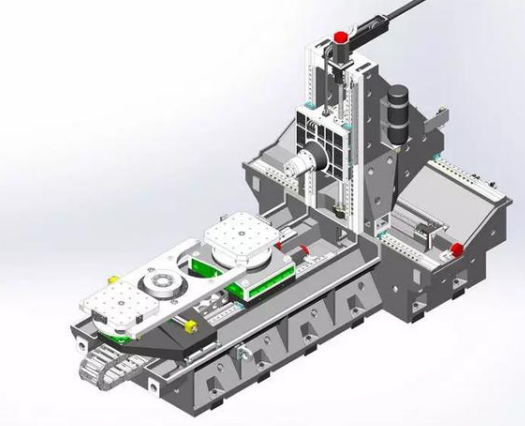

HMC50P Positive T type double worktables

group namePositive T Type

-

Min Order1 piece

brand nameZOPO INTELLIGENT EQUIPMENT MACHINING CENTER OEM

modelHMC50P

-

update timeTue, 05 Nov 2024 02:21:14 GMT

Paramtents

BRAND ZOPO CNC

CNC FANUC/SIEMENS/MITSUBISHI

SPINDLE BELT SPINDLE

CONTROL SEMI-CLOSED LOOP CONTROL

Packging & Delivery

Min Order1 piece

Briefing

Detailed

HMC50P

POSITIVE T TYPE

Ideal choice for big batch automation processing lines

750/750/750mm

X/Y/Z axis travel

500x500mm

Worktable size

5300rpm

Spindle speed

32/32/32m/min

Rapid feed speed

- Model

- Appearance

- Characteristics

- Parameters

- Contact Us

Positive T type machine body

X-axis stepped layout

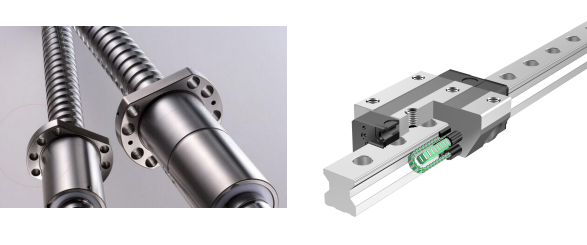

High precision double nut ball screw

High rigidity, high precision

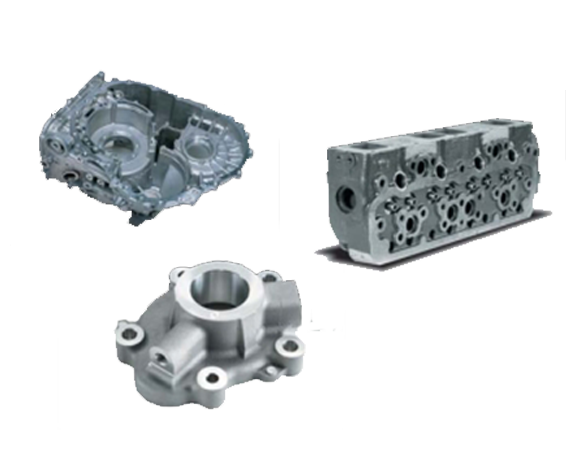

Application industry

Working range

Unit

- X/Y/Z axis travel

- 750/750/750mm

- Distance from spindle center to table surface

- 100-850mm

- Distance from spindle center to table surface

- 130-1030mm

Worktable

Unit

- Worktable size

- 500x500mm

- Workpiece clamping type

- 5-14x100mm

- Rotary diameter of workpiece

- Φ720

- Max. load bearing of worktable

- 400kg

Spindle

Unit

- Spindle hole taper

- BT50

- Spindle power

- 15/18.5KW

- Max. spindle speed

- 5300(belt)rpm

Feed

Unit

- Max. feed speed

- 6000mm/min

- Rapid feed speed

- 32/32/32m/min

Tool magzine

Unit

- Tool magzine capacity

- 24T

- Tool changing time

- 5.5S

Accuracy

Unit

- Positioning accuracy

- 0.01mm

- Re-positioning accuracy

- 0.006mm

- B axis positioning accuracy

- 10''

- B axis repositioning accuracy

- 2''

Machine

Unit

- Machine dimension

- 5850*3760*3100mm

- Machine weight

- 14000kg

You need a product

You May Like

6YRS ZOPO Intelligent Equipment CO., Ltd.