SHL60P High Application

group nameCNC Horizontal Lathe

-

Min Order1 piece

brand nameZOPO INTELLIGENT EQUIPMENT MACHINING CENTER OEM

modelSHL60P

-

update timeFri, 01 Nov 2024 13:34:19 GMT

Paramtents

Brand ZOPO Intelligent

CNC Fanuc/GNC/KND

Spindle Hole Taper A2-6

Control Mode Semi-closed loop

Packging & Delivery

Min Order1 piece

Briefing

Detailed

SHL60P

High Application

High Accuracy, Stable, High Automation

Φ600mm

Max.Swing Over Bed

500mm

Max.Turning Length

Φ400mm

Max.Turning Dia

A2-6

Spindle Hole Taper

- Model

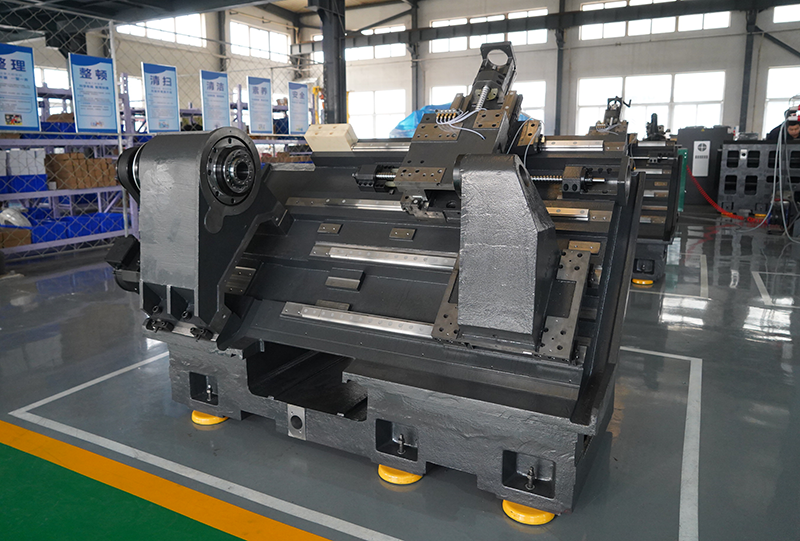

- Appearance

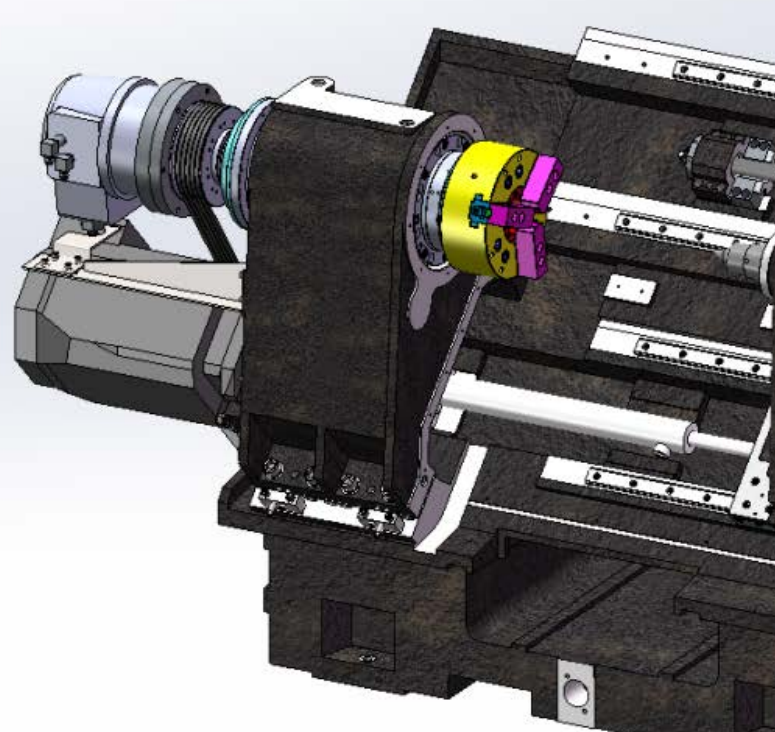

- Characteristic

- Parameters

- Contact Us

45° Machine bed design:

High Machining Accuracy

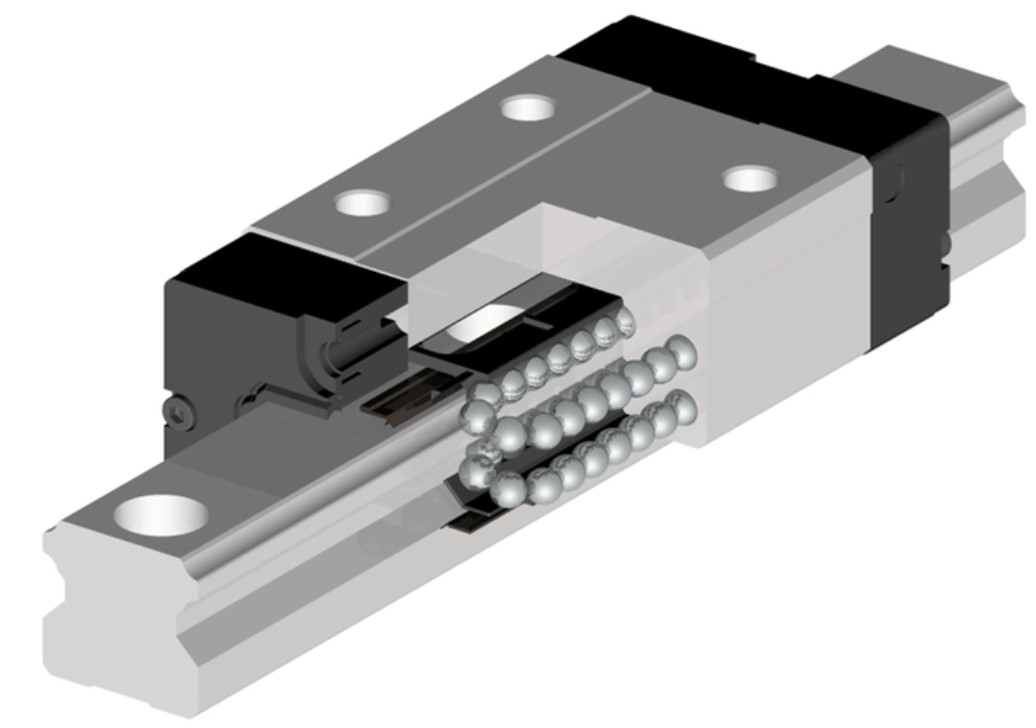

Linear Guideway

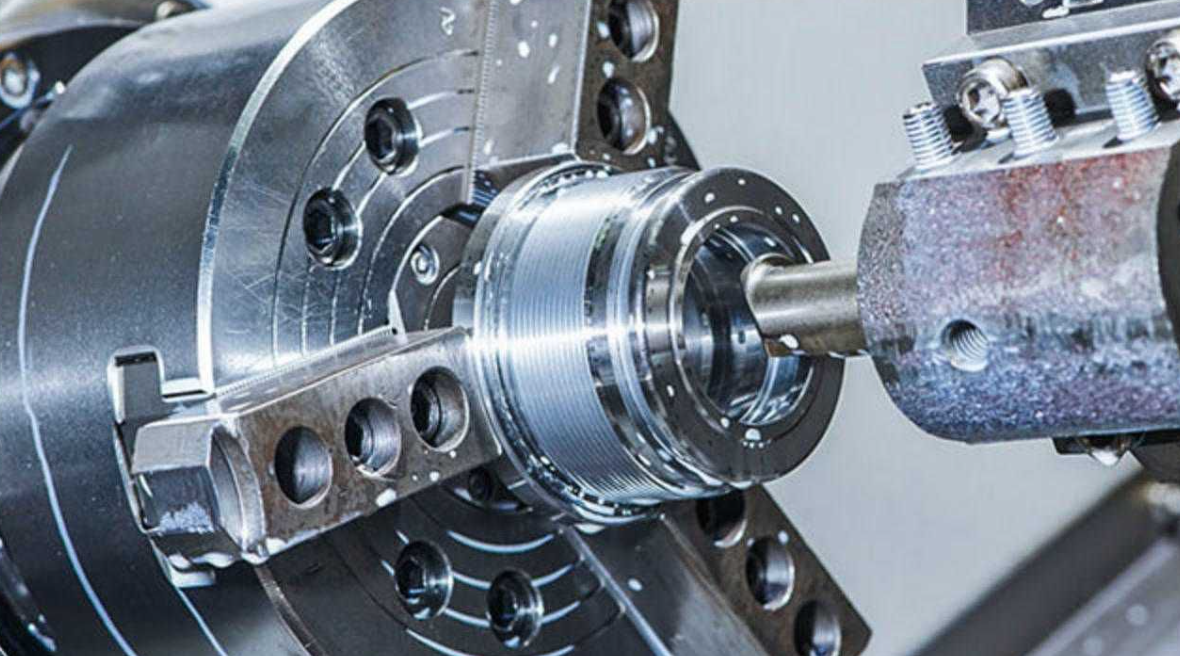

Spindle Box

Working Range

Unit

- Max. Swing Over Bed

- Φ600 mm

- Max.Turning Length

- 500 mm

- Max.Turning Dia

- Φ400 mm

- Max. Swing Over Carriage

- Φ360 mm

- X/Z Axis Travel

- 210/560 mm

Spindle

Unit

- Spindle Hole Taper

- A 2-6

- Max. Passing Bar Dia.

- Φ50 mm

- Spindle Speed Range

- 50-4500 mm

- Power

- 11/15 mm

- Standard Chuck Dia.

- 8'' inch

Feed

Unit

- Rapid Feed Rate

- 30/30m/min

Tailstock

Unit

- Tailstock Spindle Taper

- 5# T

Turret

Unit

- Standard Turret

- 8(Hydraulic)T

- Nearby Tool Select

- Yes

Machine

Unit

- Machine Dimension

- 2850*1865*1880 mm

- Machine Weight

- 4500 kg

You need a product

You May Like

6YRS ZOPO Intelligent Equipment CO., Ltd.