SVG1780 Gearhead spindle

group nameSV Series - Excellent Models

-

Min Order1 piece

brand nameZOPO INTELLIGENT EQUIPMENT MACHINING CENTER OEM

modelSVG1780

-

update timeFri, 01 Nov 2024 17:27:30 GMT

Paramtents

BRAND ZOPO INTELLIGENT

CNC system FANUC/SIEMENS/MITSUBISHI

SPINDLE Gearhead

CONTROL Semi-closed loop control

Packging & Delivery

Min Order1 piece

Briefing

Detailed

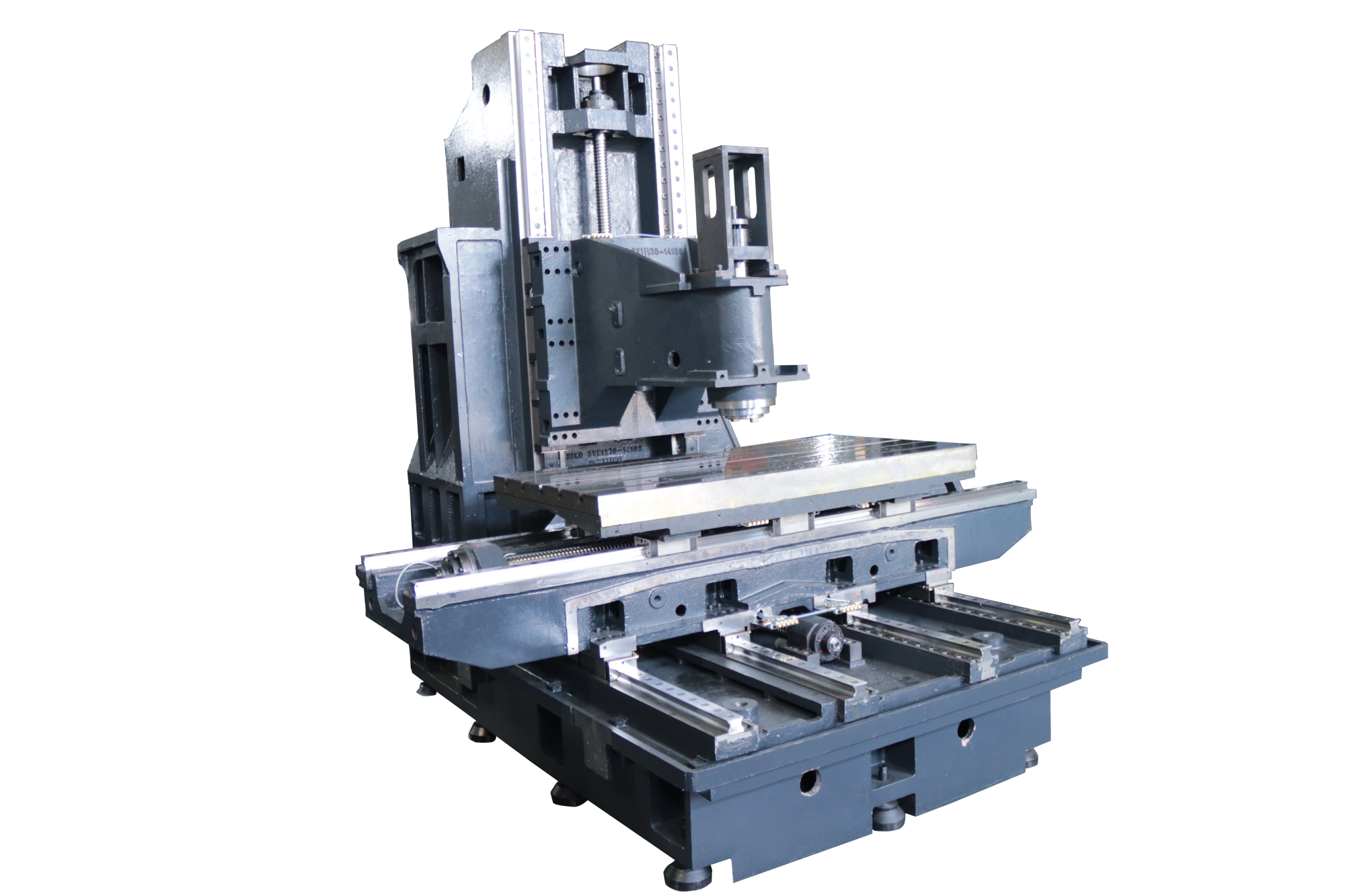

SVG1780

High rigidity and high efficiency model

The best choice for processing performance and processing range in the same level

1700/800/800mm

X/Y/Z axis travel

800×1900mm

Worktable size

6000rpm

Spindle speed

24/24/24m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Higher stability and high rigidity bed structure

- The solid dense-baked casting and integral box-type bed and arched column structure improve the basic rigidity of the machine.

- The unique cross-section design of the base component after finite element analysis and the reasonable distribution of internal reinforcement ribs give it higher load-bearing rigidity among products of the same specifications.

- The three-axis transmission seat and tail end bracket adopt an integrated casting design, eliminating the traditional split and shim adjustment mechanism, greatly improving the accuracy and stability of the machine tool's three-axis transmission.

- The Y-axis uses four 45mm high-rigidity and high-load roller linear guideways and heavy-duty 8-slide blocks to enhance rigidity and load-bearing capacity.

- Convenient and efficient chip handling: The machine tool is equipped with two screw rows as standard to effectively discharge the iron chips generated during processing, with high conveying efficiency.

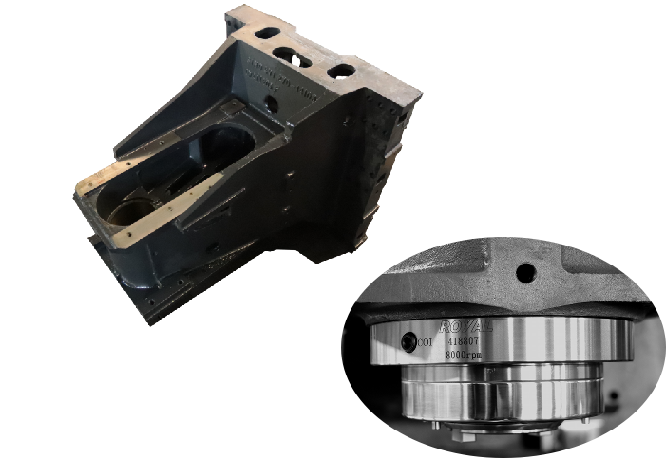

Closed spindle box

The spindle box adopts a closed box structure, the contact size with the column guideway is enlarged, and the overall lightweight design. The short nose spindle is standard, which improves the Z-axis positioning accuracy and spindle processing stability during the machine processing.

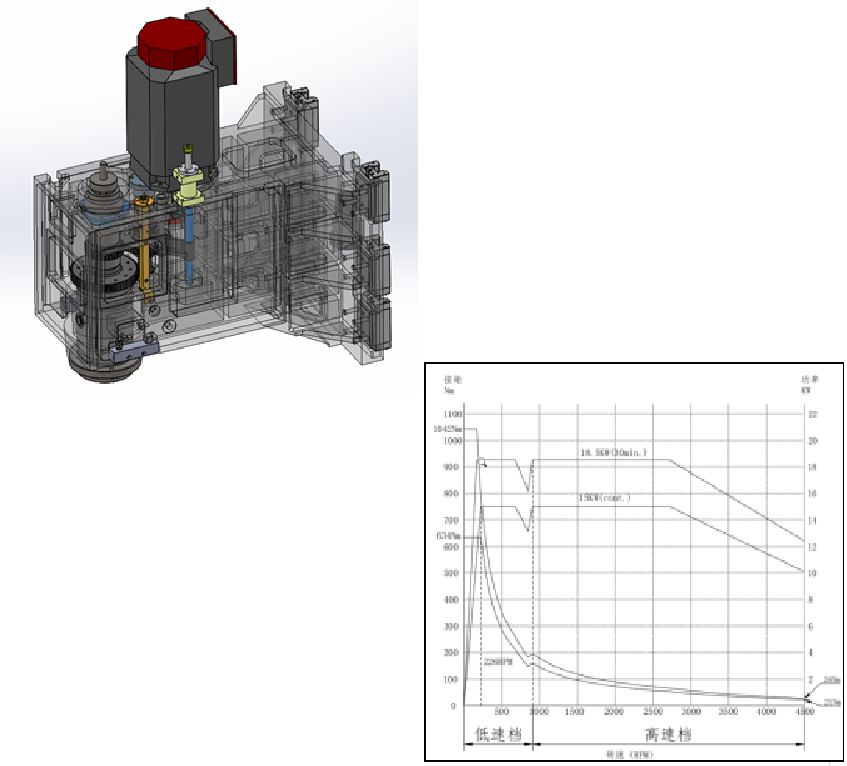

High rigidity spindle

The SVG series uses built-in gear transmission, and the 2-stage gear-driven spindle uses cylindrical roller bearings to ensure strong torque at low speed and stable speed at high speed to meet customers' diverse processing needs. The maximum torque at low speed can reach 1042Nm.

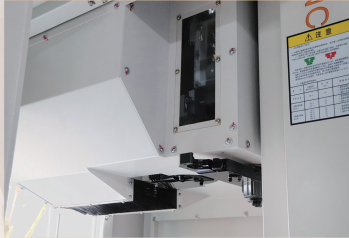

Stable and reliable tool changing device

Working range

Unit

- X/Y/Z axis travel

- 1700/800/800mm

- Distance from column to spindle center

- 887mm

- Distance from table surface to spindle nose

- 180-980mm

Worktable

Unit

- Worktable size

- 800x1900mm

- T-slot size

- 5-22*160mm

- Max. load bearing of worktable

- 1300kg

Spindle

Unit

- Spindle hole taper

- BT50

- Main motor power

- 15/18.5(Wide area)KW

- Spindle speed

- 6000(Gearhead)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 24/24/24m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 3.5S

Accuracy

Unit

- Positioning accuracy

- 0.001mm

- Re-positioning accuracy

- 0.005mm

Machine

Unit

- Machine dimension

- 5500*3250*3560mm

- Machine weight

- 16500kg

You need a product

Related Searches

You May Like

6YRS ZOPO Intelligent Equipment CO., Ltd.